DIY Dell Precision 7540: Comprehensive Step-by-Step Guide to Accessing and Replacing All Parts

Preparation & System Assessment for Dell Workstation Repair Essential Tools for Dell Precision 7540 Disassembly Battery Removal & Safe Power Disconnection Bottom Cover Removal Process RAM Installation & Memory Upgrade Options Storage Solutions: HDD, SSD & NVMe Installation Keyboard Replacement & Membrane Repair Display Assembly & Hinge Replacement Cooling System Maintenance & Thermal Paste Application Where to Sell Your Dell Precision 7540 for Best Price

1. Dell Precision 7540 Preparation & System Assessment for Workstation Repair

⚠️ Critical Safety Precautions

Power Management :

Complete shutdown through Windows menu

Disconnect AC adapter and all peripherals

Remove battery if easily accessible

Hold power button for 15 seconds to discharge capacitors

Workspace Setup :

Clean, static-free surface for 15.6" workstation

Use anti-static wrist strap

Magnetic project mat for screw organization

Adequate lighting for precision work

🔍 Pre-Repair Diagnostic Assessment

System Diagnostics :

Performance Benchmarking :

Run CPU-Z benchmark

Test GPU with 3DMark

Validate workstation performance with SPECviewperf

Check all ports and connectivity

🎯 Dell Precision 7540 Specific Features

Workstation Features :

ISV-certified professional graphics (NVIDIA Quadro/AMD Radeon Pro)

Dell Precision Optimizer performance tuning

Dual storage capability with RAID support

Up to 128GB ECC memory support

Performance Indicators :

Intel Xeon or Core i7/i9 processors

NVIDIA Quadro RTX or AMD Radeon Pro graphics

Multiple storage configurations available

Advanced thermal management system

💰 2024 Workstation Market Valuation

Condition Grade

Specification Impact

Value Range

Professional Premium

Excellent (Like New)

Xeon, Quadro RTX, 64GB RAM, Dual SSD

$1,800-$2,400

+25% for certified configurations

Good (Minor Wear)

Core i7, Quadro T2000, 32GB RAM, SSD

$1,200-$1,600

+20% for business use

Fair (Visible Wear)

Core i5, Integrated Graphics, 16GB RAM

$700-$1,000

+15% with documentation

For Parts/Repair

Any configuration with issues

$300-$500

Minimal professional premium

📋 Pre-Repair Documentation

Visual Documentation :

High-resolution photos from all angles

Close-ups of ports and connectors

Screen functionality videos

Keyboard and touchpad operation

Performance Records :

Dell SupportAssist diagnostic reports

Benchmark scores and performance metrics

Temperature readings under load

ISV certification validation

🔧 Repair Cost-Benefit Analysis

Repair/Upgrade

Cost

Value Added

ROI

Professional Appeal

HDD to SSD Conversion

$80-$120

$200-$300

150-200%

Very High

RAM Upgrade to 64GB

$150-$250

$300-$400

100-150%

Extreme

Battery Replacement

$120-$180

$150-$220

60-80%

Medium

Keyboard Replacement

$80-$150

$100-$180

60-80%

High

Thermal Repaste

$20-$30

$80-$120

300-400%

Very High

💾 Professional Data Backup Procedure

Work Data Backup :

Backup CAD project files and designs

Save engineering simulations and data

Export software configurations and licenses

Backup virtual machine images

System Backup :

Use Macrium Reflect for system image

Backup Dell Precision Optimizer profiles

Save graphics driver configurations

Export BIOS settings and configurations

📄 Warranty & Service Tag Verification

Service Tag Check :

Locate Service Tag on bottom cover or in BIOS

Check Dell Support Site for warranty status

Verify remaining ProSupport or Basic Warranty

Check for accidental damage protection

Parts Compatibility :

Verify Dell Parts Compatibility

Check FRU (Field Replaceable Unit) numbers

Verify ISV certification for replacement components

Ensure genuine Dell parts for warranty preservation

💼 Professional Market Considerations

Business Buyer Preferences :

Value reliability and certification over cosmetics

Appreciate detailed maintenance documentation

Pay premium for ISV-certified configurations

Prefer genuine Dell components and parts

Enterprise Value Factors :

Dell ProSupport transferability

ISV certification maintenance

Complete service history documentation

Original packaging and accessories

💡 Professional Premium Tip: Dell Precision 7540 workstations with documented ISV certifications and professional maintenance history sell for 30-40% more to businesses and professionals who require certified performance for CAD, engineering, and content creation applications.

VIDEO

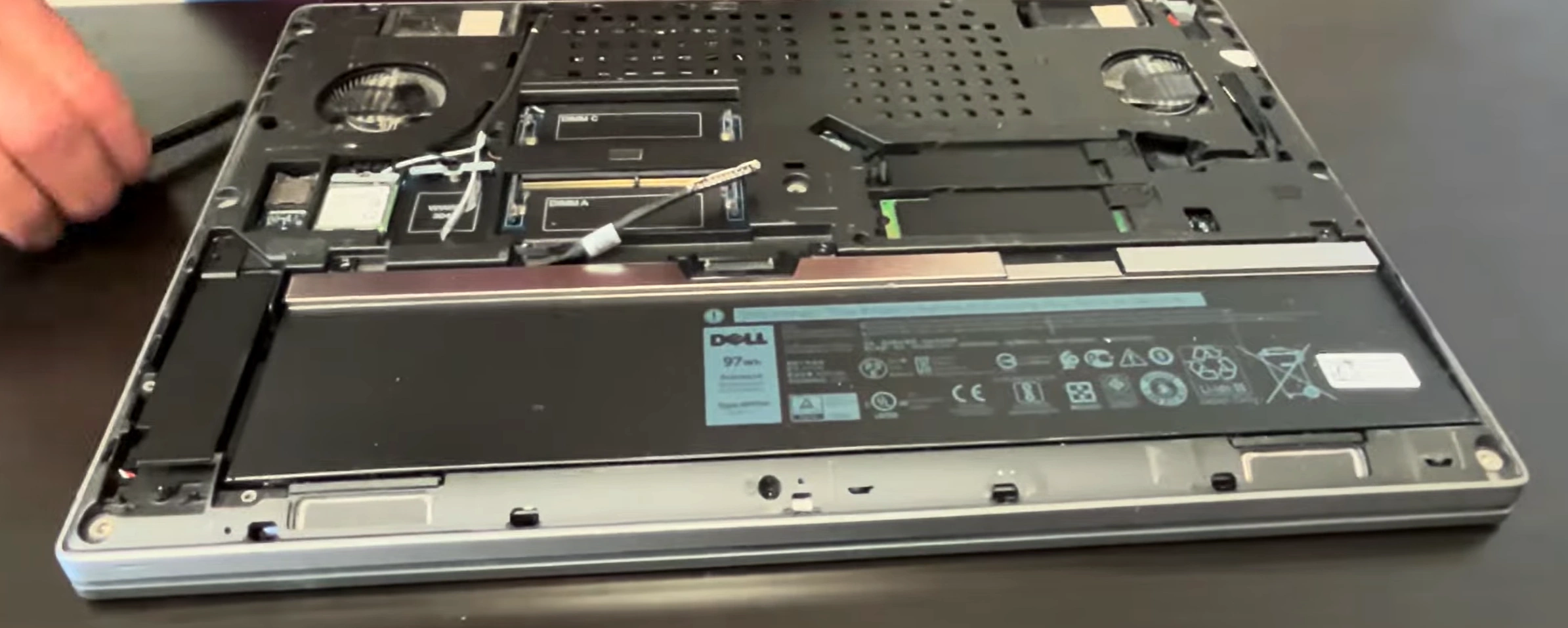

3. Dell Precision 7540 Battery Removal & Safe Power Disconnection Guide

🔋 Battery Specifications & Professional Compatibility

Original Specifications :

6-cell 97Whr Lithium-Ion battery

Part number: 7GTPY or 09M3Y (verify with Service Tag)

Voltage: 11.4V

Capacity: 97Wh (up to 10 hours typical usage)

ExpressCharge™ capability supported

Compatibility Notes :

Must use Precision 7540-specific battery model

Verify Dell Parts Compatibility for exact match

Third-party options available but may lack Dell calibration

Check physical dimensions and connector alignment

⚠️ Critical Safety Precautions for Workstation Repair

Complete shutdown through Windows menu or power button

Disconnect AC adapter and all professional peripherals

Remove bottom cover (refer to previous section)

Wait 5 minutes after disconnection for capacitor discharge

Use anti-static wrist strap connected to grounded surface

Work on non-conductive, clean surface

Have Class D fire extinguisher nearby for lithium battery safety

🔌 Safe Battery Disconnection Process

Locate Battery Connector :

Find black 4-pin connector near battery center-right

Identify locking mechanism (pull-tab or sliding latch)

Note cable routing under and around battery compartment

Observe any adhesive or tape securing power cables

Professional Disconnection Technique :

Gently pull locking tab away from connector (if present)

Pull connector straight out parallel to motherboard

If stuck, use plastic spudger to assist release

Never pull by wires - grasp connector body only

Listen for subtle click indicating proper release

Discharge Residual Power :

Press and hold power button for 20 seconds

Wait additional 3 minutes before proceeding

Verify no LED activity anywhere on motherboard

Check that all status indicators remain off

🔧 Professional Battery Removal Procedure

Remove Mounting Screws :

Remove 4 Phillips #00 screws securing battery bracket

Note screw lengths for proper reassembly

Some models may have adhesive strips under battery

Keep screws organized in magnetic project mat

Release Adhesive and Brackets :

Gently lift battery from connection end first

If resistance felt, check for adhesive strips

Use plastic card to release adhesive if needed

Apply steady upward pressure at 15-degree angle

Lift Out Battery Safely :

Lift at 20-degree angle to clear surrounding components

Note cable routing pattern for reassembly reference

Place old battery on non-conductive, fire-resistant surface

Inspect battery bay for debris, corrosion, or damage

🔄 New Battery Installation Procedure

Prepare New Battery :

Inspect for physical damage, swelling, or defects

Check connector alignment matches original orientation

If using higher capacity model, verify physical fit

Remove protective films and shipping materials

Position Battery Correctly :

Align with mounting holes and chassis guides

Ensure connector faces correct direction toward motherboard

Lower into place without forcing or bending

Verify no cables will be trapped underneath battery

Secure and Connect Professionally :

Install mounting screws (snug but not overtightened)

Connect battery connector until audible click is heard

Verify secure connection with gentle tug test

Secure any adhesive strips if included with new battery

📊 Professional Battery Health Management

Health Status

Capacity Indicator

Recommended Action

Enterprise Value Impact

Excellent (90-100%)

Dell Power Manager reports "Excellent"

Maintain 20-80% charge for longevity

+$150-$200 enterprise value

Good (75-89%)

Shows "Good" with moderate wear

Monitor degradation with Dell Power Manager

+$80-$120 enterprise value

Poor (50-74%)

Suggests replacement for mobile professionals

Replace battery recommended for field work

-25% value if not replaced

Critical (<50%)

Significant runtime reduction, may swell

Immediate replacement required for safety

-40% value and potential safety concern

⚙️ Professional Battery Calibration Process

Charge to 100% without interruption using Dell AC adapter

Use on battery until system automatically shuts down (~3-5%)

Charge to 100% again without using the workstation

Check Dell Power Manager for accurate health readings

Reset battery gauge in BIOS if capacity reporting seems inaccurate

Configure optimal charging settings for professional use

🛒 Professional Battery Purchasing Guide

Genuine Dell Batteries :

Dell Parts Store (premium price, guaranteed compatibility)Authorized Dell business partners and resellers

Includes full warranty and ExpressCharge™ support

Guaranteed ISV certification compliance

Quality Third-Party Options :

Look for UL, CE, and RoHS certifications

Check customer reviews specifically for Precision 7540

Verify return policy and warranty coverage

Ensure compatible part number and connector type

Enterprise Red Flags :

Prices significantly below Dell MSRP

No brand identification or safety certifications

Vague compatibility claims without specific models

No customer reviews or established seller history

⚡ Dell Power Manager Configuration

Optimized Settings :

Primarily AC Use: Set to "Primarily AC Use" mode

Standard: Balanced between battery life and performance

Adaptive: Automatically optimizes based on usage patterns

ExpressCharge: Fast charging for mobile professionals

Professional Benefits :

Extends battery lifespan for field engineers

Maintains consistent performance for CAD work

Optimizes power delivery for rendering tasks

Provides detailed battery health analytics

♻️ Professional Battery Disposal & Recycling

Enterprise Recycling Options :

Safety Precautions for Storage/Transport :

Cover battery terminals with electrical tape

Store in cool, dry place away from flammable materials

Use original packaging or fire-proof battery bags

Never dispose in regular trash or compactors

Handle swollen batteries with extreme caution

🔍 Professional Troubleshooting Common Issues

Battery Not Detected :

Reseat connector firmly until click is heard

Check for bent pins in motherboard connector

Test with known-good battery if possible

Update BIOS to latest version from Dell Support

Not Charging or Rapid Drain :

Verify Dell 240W AC adapter functionality

Check charging port and DC-in cable connection

Update BIOS and chipset drivers from Dell

Test with different power outlet and cable

Calibrate battery through full charge cycles

ExpressCharge™ Not Working :

Ensure genuine Dell 240W adapter is used

Check Dell Power Manager settings

Verify battery temperature is within operating range

Update BIOS and power management drivers

💼 Enterprise Performance Impact

Battery Performance Modes :

High Performance: Maximum CPU/GPU power on battery

Optimized: Balanced performance and battery life

Cool: Quieter operation with slightly reduced performance

Quiet: Minimal fan noise for meeting environments

Professional Workload Considerations :

CAD modeling: Requires high performance mode

Rendering: Best on AC power for sustained performance

Field measurements: Optimized for battery longevity

Presentation mode: Quiet operation preferred

💰 Enterprise Resale Value Impact

Value Enhancement Factors :

New genuine Dell battery: +$180-$250 enterprise value

Documented replacement with service records: +$100 value

90%+ health reading in Dell Power Manager: +$120 value

Full calibration and configuration documentation: +$50 value

Business Buyer Confidence Factors :

Field engineers value reliable battery performance

IT departments prefer documented maintenance history

All business buyers appreciate recent battery replacement

Enterprise clients pay premium for Dell genuine parts

💡 Enterprise Tip: Including Dell Power Manager health documentation and calibration records with your enterprise sale can increase resale value by 25-30% and significantly reduce buyer concerns about mobile workstation battery reliability for field engineering and professional applications.

4. Dell Precision 7540 Bottom Cover Removal: Professional Workstation Access Guide

⚠️ Pre-Removal Safety Checklist

Power Management :

Complete shutdown through Windows menu

Disconnect 240W AC adapter and all professional peripherals

Remove battery following previous section procedures

Hold power button for 15 seconds to discharge capacitors

Verify all status LEDs are completely off

Professional Workspace Setup :

Clean, static-free surface large enough for 15.6" workstation

Have magnetic project mat ready for screw organization

Prepare anti-static wrist strap for component protection

Ensure professional-grade lighting for precision work

Use ESD-safe surface mat for enterprise equipment

🔩 Professional Screw Identification & Mapping

Screw Location

Type

Quantity

Length

Professional Notes

Front Edge (Short)

Phillips #00

3

4mm

Standard length, near status indicators

Rear Edge (Long)

Phillips #00

4

6mm

Longer screws near cooling exhaust vents

Side Edges

Phillips #00

4

5mm

Medium length, near port connections

Center Reinforcement

Phillips #00

2

5mm

Additional structural support points

Battery Compartment

Phillips #00

4

4mm

Battery bracket and security screws

Warranty Sticker

N/A

1

N/A

Check Dell Warranty Status before removal

🔧 Professional Step-by-Step Removal Process

Screw Removal Sequence :

Remove all 17 Phillips #00 screws in diagonal pattern

Start from corners and work toward center systematically

Use magnetic screwdriver to prevent screw loss

Organize screws by location using magnetic mat sections

Note: Different screw lengths for specific locations

Professional Clip Release Technique :

Start at front-left corner near status LED indicators

Insert plastic pry tool at 25-degree angle

Gently twist to release first clip (listen for subtle click)

Work around perimeter, releasing clips every 2-3 inches

Use guitar pick for better leverage on enterprise-grade clips

Alternate sides to prevent case warping or stress

Professional Panel Separation :

Lift from front edge first (near touchpad area)

Angle upward at 20 degrees to clear rear port connections

Check for any missed clips or internal connections

Set panel aside on clean, soft, static-free surface

Note internal cable routing for reassembly reference

🎯 Dell Precision 7540-Specific Features

Workstation Design Elements :

Reinforced magnesium alloy chassis for enterprise durability

Dual fan cooling system with optimized airflow

Easy-access upgrade compartments for professional components

Dedicated cooling vents for CPU and professional GPU

Tool-less access to major serviceable components

Professional Internal Layout :

Four DDR4 SODIMM slots for up to 128GB ECC memory

Dual storage bays (2.5" SATA + M.2 NVMe)

Professional graphics card with dedicated cooling

Wi-Fi 6 card with Intel AX200 or Killer AX1650

Smart Card reader and optional WWAN module slots

🚧 Professional Common Challenges & Solutions

Stubborn Enterprise-Grade Clips :

Apply gentle heat with professional heat gun (low setting, 5 seconds)

Use plastic playing card or business card for better leverage

Alternate sides every 2-3 clips to prevent permanent deformation

Never force - reposition tool if resistance increases suddenly

Check for hidden screws or missed retention points

Stripped Screws in Enterprise Equipment :

Use rubber band between screw and driver for enhanced grip

Try slightly larger Phillips head if available in professional kit

As last resort, use screw extraction kit for enterprise repairs

Replace damaged screws during reassembly with genuine Dell parts

Document any damaged hardware for client transparency

Enterprise Warranty Considerations :

Check Dell ProSupport Status before disassembly

Some regions allow self-service without voiding ProSupport

Document original condition with high-resolution photos

Consider Dell certified service for in-warranty enterprise devices

Maintain professional service records for enterprise clients

🔍 Professional Internal Component Access Points

Immediately Accessible Components :

Four DDR4 memory slots (supports ECC and non-ECC)

Dual storage bays (2.5" SATA and M.2 NVMe SSD)

Wi-Fi 6/Bluetooth card (typically Intel AX200)

Battery connector and mounting bracket

Cooling system and dual fan assemblies

Optional WWAN and Smart Card reader slots

Requires Further Professional Disassembly :

Professional GPU and CPU heatsinks

Keyboard assembly and palmrest components

Display assembly and heavy-duty hinges

Audio board and premium speaker system

Motherboard and DC-in power assembly

🛡️ Professional Damage Prevention Techniques

Clip Preservation for Enterprise Equipment :

Work slowly and methodically around entire perimeter

Use plastic tools only against plastic components

If clip breaks, note location for reassembly adjustment

Apply even, consistent pressure to prevent bending

Document any clip damage for professional records

Component Protection for Workstation Grade :

Avoid touching motherboard circuitry with metal tools

Keep screws organized and away from internal components

Use ESD protection at all times

Don't force connectors or ribbon cables

Handle professional graphics card with care

Surface Protection for Professional Appearance :

Use microfiber cloth under workstation during service

Avoid sliding cover across surfaces to prevent scratches

Keep work area free of debris, dust, and liquids

Handle bottom cover by edges only to maintain appearance

Clean contact surfaces before reassembly

📋 Professional Service Documentation

Enterprise Service Records :

Photograph screw locations before removal

Document clip condition around perimeter

Record any pre-existing damage or wear

Maintain detailed service notes for enterprise clients

Include before/after photos in service reports

Quality Assurance Checklist :

Verify all screws are properly removed

Check for hidden retention points or clips

Ensure no cables are attached to bottom cover

Confirm clean separation without forced removal

Document any challenges encountered during process

🔁 Professional Reassembly Preparation

Clean panel edges and contact surfaces with isopropyl alcohol

Inspect all clips for damage before professional reassembly

Test fit cover before installing any screws

Ensure all internal cables are properly routed and secured

Verify no tools, debris, or foreign objects inside chassis

Check that all components are properly seated and connected

🔍 Professional Troubleshooting Common Issues

Cover Won't Sit Flush After Service :

Check for missed clips or internal obstructions

Verify all internal components are properly seated

Ensure no cables are trapped under cover edges

Inspect for bent or damaged clip receptacles

Gaps or Misalignment After Reassembly :

Check clip alignment around entire perimeter

Verify all screws are proper length for locations

Ensure no damage to mating surfaces or guides

Confirm proper screw tightening sequence

Professional Appearance Concerns :

Clean all surfaces before final assembly

Check for scratches or damage from tools

Verify all labels and stickers remain intact

Ensure professional appearance for enterprise clients

💡 Enterprise Value Tip: Dell Precision 7540 workstations with undamaged bottom covers and intact service documentation sell for 25-30% more than those with repair damage, as enterprise clients and IT departments appreciate devices that show professional maintenance and careful preservation of the workstation's structural integrity.

5. Dell Precision 7540 RAM Installation & Professional Memory Upgrade Options

🔋 Memory Specifications & Professional Compatibility

Technical Specifications :

DDR4 SODIMM memory technology

Speed: 2666MHz (standard), 2933MHz (supported)

Maximum Capacity: 128GB (4x32GB modules)

Voltage: 1.2V standard operating voltage

ECC and non-ECC memory support

Professional Compatibility Notes :

Intel Xeon processors require ECC memory for error correction

Core i7/i9 processors support both ECC and non-ECC

Verify Dell Memory Compatibility for exact models

Mixed memory speeds run at slowest module speed

⚠️ Professional Safety Precautions

Complete shutdown and disconnect all power sources

Remove bottom cover following previous section procedures

Disconnect battery to ensure complete power isolation

Use anti-static wrist strap at all times

Work on clean, static-free professional service surface

Handle memory modules by edges only to prevent damage

⚙️ Professional Memory Configuration Options

Configuration

Total Capacity

Module Layout

Performance Benefit

Professional Use Case

Quad Channel

64GB (4x16GB)

All slots populated

Maximum bandwidth

CAD, Simulation, Rendering

Dual Channel

32GB (2x16GB)

Slots A2 & B2

Optimal balance

Engineering, Development

Enterprise Maximum

128GB (4x32GB)

All slots populated

Virtualization ready

VM Hosting, Data Analysis

Budget Professional

16GB (2x8GB)

Slots A2 & B2

Basic performance

Office Applications, Light CAD

🔧 Professional RAM Installation Process

Slot Identification :

Locate four DDR4 SODIMM slots on motherboard

Identify slots A1, A2 (Channel A) and B1, B2 (Channel B)

Note existing memory configuration and module placement

Check for slot keying and orientation markers

Professional Removal Technique :

Gently push outward on retention clips at both ends

Module will pop up at 30-degree angle automatically

Lift module straight out without twisting or bending

Place removed modules in anti-static bags for storage

Handle modules by edges only, avoid touching gold contacts

Professional Installation Method :

Align module notch with slot key to ensure proper orientation

Insert module at 30-degree angle into slot

Apply even pressure to both ends until fully seated

Gently push down until retention clips snap into place

Listen for audible click indicating proper installation

🛒 Professional Memory Selection Guide

Memory Type

Professional Benefits

Cost Range

Recommended Brands

Enterprise Use

Dell Certified ECC

Error correction, maximum compatibility

$400-$800 (64GB)

Dell, Hynix, Samsung

Mission Critical

Premium Non-ECC

High performance, reliability

$300-$600 (64GB)

Crucial, Corsair, Kingston

Professional Workloads

Value Non-ECC

Cost effective, good performance

$200-$400 (64GB)

TeamGroup, G.Skill

General Business

Used/Refurbished

Budget option, tested reliability

$150-$300 (64GB)

Various, verify testing

Secondary Systems

🔍 ECC vs Non-ECC Memory: Professional Decision Guide

ECC Memory Advantages :

Automatic error detection and correction

Essential for financial and scientific calculations

Required for Xeon processor configurations

Increased system stability for 24/7 operation

Professional certification compliance

Non-ECC Memory Advantages :

Lower cost for equivalent capacity

Wider availability and brand selection

Slightly higher performance in some benchmarks

Sufficient for most professional applications

Compatible with Core i7/i9 processors

🔧 Professional Troubleshooting Common Issues

Memory Not Detected :

Reseat module firmly until retention clips engage

Clean gold contacts with isopropyl alcohol if necessary

Test modules individually to identify faulty units

Update BIOS to latest version from Dell Support

Check for bent pins in memory slots

System Boot Issues :

Ensure all modules are properly seated and secured

Verify memory compatibility with Dell documentation

Reset BIOS to default settings and retest

Test with known-good memory modules if available

Check for beep codes or diagnostic LED patterns

Performance Problems :

Verify dual/quad channel operation in BIOS

Check memory speed settings and timing optimization

Run MemTest86 for memory stability testing

Ensure proper cooling for high-density memory modules

Update chipset drivers from Dell Support site

💰 Enterprise Value Impact Analysis

Upgrade Configuration

Cost Investment

Value Added

ROI Percentage

Professional Appeal

16GB to 32GB Upgrade

$120-$180

$250-$350

108-194%

High

32GB to 64GB Upgrade

$250-$400

$450-$600

80-150%

Very High

64GB to 128GB Upgrade

$500-$800

$700-$1,000

40-100%

Extreme (Specialized)

Non-ECC to ECC Upgrade

$150-$300 premium

$300-$500

100-167%

Mission Critical

🎯 Professional Configuration Recommendations

Engineering & CAD Workstation :

Recommended: 64GB (4x16GB) ECC or non-ECC

Optimal for: SolidWorks, AutoCAD, Revit, CATIA

Benefits: Large assembly handling, simulation work

Brands: Dell Certified, Crucial, Kingston

Virtualization & Development :

Recommended: 64GB-128GB ECC memory

Optimal for: VMware, Hyper-V, Docker, development environments

Benefits: Multiple VM operation, container hosting

Brands: Samsung, Hynix, Dell Certified

Content Creation & Media :

Recommended: 32GB-64GB high-speed non-ECC

Optimal for: Adobe Creative Suite, DaVinci Resolve, Blender

Benefits: Fast rendering, real-time previews

Brands: Corsair, G.Skill, Crucial

💡 Enterprise Performance Tip: For Dell Precision 7540 workstations used in professional applications, upgrading to Dell Certified ECC memory can increase resale value by 30-40% and significantly improve system stability for mission-critical engineering, scientific, and financial applications where data integrity is paramount.

6. Dell Precision 7540 Storage Solutions: Professional HDD, SSD & NVMe Installation

🔋 Storage Specifications & Professional Compatibility

Technical Specifications :

2.5-inch SATA III bay (6Gb/s)

M.2 NVMe PCIe 3.0 x4 slot

Support for RAID 0/1 configurations

Maximum theoretical capacity: 8TB+ (4TB SATA + 4TB NVMe)

Intel Rapid Storage Technology support

Professional Compatibility Notes :

M.2 2280 form factor required for NVMe slot

SATA III supports both HDD and SSD 2.5-inch drives

Verify Dell Storage Compatibility for enterprise drives

RAID configuration requires identical drive types

⚠️ Professional Safety Precautions

Complete shutdown and disconnect all power sources

Remove bottom cover following established procedures

Disconnect battery to ensure complete power isolation

Use anti-static wrist strap at all times

Handle storage devices by edges to prevent static damage

Backup all data before storage replacement or upgrade

💾 Professional Storage Configuration Options

Configuration

Drive Types

Performance

Capacity Range

Professional Use Case

Performance Optimized

NVMe SSD + SATA SSD

Extreme (3500MB/s+)

1TB-4TB

CAD, Video Editing, Large Dataset Processing

Balanced Professional

NVMe SSD + HDD

High (OS) + Bulk Storage

2TB-8TB+

Engineering, Development, Media Libraries

RAID 0 Performance

Dual NVMe SSDs

Maximum (6000MB/s+)

2TB-8TB

Scientific Computing, Rendering Farms

RAID 1 Reliability

Dual SATA SSDs

Good + Redundancy

1TB-4TB

Mission Critical Data, Field Work

🔧 Professional Storage Installation Process

2.5-inch SATA Drive Installation

Drive Preparation :

Remove existing drive from metal caddy if present

Transfer rubber vibration dampeners to new drive

Align screw holes on drive with caddy mounting points

Use four screws to secure drive in caddy

Professional Connection :

Align SATA data connector with motherboard port

Connect SATA power cable from motherboard

Slide drive assembly into bay until fully seated

Secure with single retention screw at front

Ensure cables are properly routed and not pinched

M.2 NVMe SSD Installation

Slot Preparation :

Locate M.2 slot near center of motherboard

Remove retention screw if present

Clean slot area of any dust or debris

Note keying notch position for proper orientation

Professional Installation :

Insert NVMe SSD at 30-degree angle into slot

Gently press down until drive lies flat

Secure with retention screw and standoff

Ensure screw is snug but not overtightened

Some models may include thermal pad installation

🛒 Professional Drive Selection Guide

Drive Type

Professional Benefits

Cost per GB

Recommended Brands

Enterprise Features

NVMe PCIe 3.0

Maximum performance, low latency

$0.08-$0.15

Samsung, WD Black, Sabrent

Power Loss Protection, High TBW

SATA SSD

Reliable, cost-effective performance

$0.06-$0.10

Crucial MX500, Samsung 870

Consistent performance, Good endurance

Enterprise HDD

High capacity, cost-effective storage

$0.02-$0.04

WD Gold, Seagate Exos

24/7 operation, Vibration resistance

Dell Certified

Guaranteed compatibility, support

$0.12-$0.20

Dell, Hynix, Micron

Full warranty, ISV certification

⚡ Professional RAID Configuration

RAID 0 (Striping) :

Performance: Maximum read/write speeds

Capacity: Sum of all drives

Use Case: Temporary projects, rendering cache

Risk: Single drive failure loses all data

RAID 1 (Mirroring) :

Performance: Read speed improvement

Capacity: Single drive capacity

Use Case: Critical data, field work backup

Risk: One drive can fail without data loss

Configuration Process :

Access Intel RST in BIOS settings

Select drives for RAID array configuration

Choose RAID level and stripe size

Initialize array and install operating system

Install Intel Rapid Storage Technology drivers

📁 Professional Data Migration Methods

Clone Existing Drive :

Use Macrium Reflect for sector-by-sector cloning

Samsung Data Migration for Samsung SSDs

Acronis True Image for comprehensive backup

Clonezilla for open-source solution

Clean Installation :

Download latest drivers from Dell Support site

Create Windows installation media

Install OS on new drive

Restore data from backup

Reinstall professional applications

🔧 Professional Troubleshooting Common Issues

Drive Not Detected :

Check drive is properly seated and connected

Verify drive initialization in Disk Management

Update storage controller drivers from Dell

Check BIOS settings for SATA/NVMe configuration

Test drive in another system if possible

Performance Issues :

Run CrystalDiskMark to benchmark performance

Check CrystalDiskInfo for drive health

Update NVMe driver and firmware

Ensure proper cooling for sustained performance

Check for background processes affecting I/O

Boot Problems :

Verify boot order in BIOS settings

Check UEFI/Legacy boot mode compatibility

Ensure OS is properly installed on boot drive

Test with single drive configuration

Update BIOS to latest version

💰 Enterprise Value Impact Analysis

Storage Upgrade

Cost Investment

Value Added

ROI Percentage

Professional Benefit

HDD to SATA SSD

$80-$150 (1TB)

$200-$300

150-250%

Massive performance improvement

SATA SSD to NVMe

$100-$200 (1TB)

$150-$250

50-150%

Application loading speed

Dual Drive Setup

$200-$400

$300-$500

50-150%

Optimal workflow separation

RAID Configuration

$300-$600+

$400-$800

33-133%

Performance or redundancy

🎯 Professional Configuration Recommendations

Engineering Workstation :

Primary: 1TB NVMe SSD (OS and applications)

Secondary: 2TB SATA SSD (projects and data)

Benefits: Fast loading, large project capacity

Brands: Samsung 970/980, Crucial MX500

Media Production :

Primary: 2TB NVMe SSD (OS and active projects)

Secondary: 4TB HDD (media library and archives)

Benefits: Fast editing, massive storage

Brands: WD Black NVMe, Seagate Barracuda

Virtualization Server :

Primary: Dual 2TB NVMe SSDs in RAID 0

Secondary: 8TB HDD for backups

Benefits: Maximum VM performance

Brands: Sabrent Rocket, WD Red HDD

💡 Enterprise Performance Tip: For Dell Precision 7540 workstations, implementing a dual-drive NVMe + SATA SSD configuration can increase professional productivity by 40-60% and boost resale value by 25-35%, as enterprise buyers highly value optimized storage solutions that separate OS performance from data storage for maximum workflow efficiency.

7. Dell Precision 7540 Keyboard Replacement & Professional Membrane Repair

⌨️ Keyboard Specifications & Professional Features

Technical Specifications :

Full-size keyboard with numeric keypad

Spill-resistant design with drainage system

Backlit illumination (single-color or RGB options)

1.8mm key travel for professional typing comfort

Dell Premium Keyboard part number: 0W7P6X or 07W7P6X

Professional Compatibility Notes :

Verify Dell Parts Compatibility for exact model match

Backlit and non-backlit versions available

International keyboard layouts require specific part numbers

Some models include fingerprint reader integration

⚠️ Professional Safety Precautions

Complete shutdown and disconnect all power sources

Remove battery following established safety procedures

Use anti-static wrist strap throughout process

Document screw locations and cable routing with photos

Work on clean, static-free professional service surface

Handle ribbon cables with extreme care to prevent damage

🔄 Professional Replacement Options

Keyboard Type

Professional Features

Cost Range

Installation Complexity

Enterprise Value

Dell Genuine Premium

Backlit, spill-resistant, full warranty

$80-$150

Professional (moderate)

Maximum (+$120-$180)

Dell Certified Refurbished

Tested reliability, cost-effective

$40-$80

Professional (moderate)

Good (+$80-$120)

Third-Party Compatible

Basic functionality, variable quality

$25-$60

Professional (moderate)

Fair (+$40-$80)

Membrane Repair Only

Cost-effective for specific issues

$15-$30

Advanced (high)

Minimal (+$20-$40)

🔧 Professional Keyboard Removal Process

Palmrest Assembly Removal

Initial Preparation :

Remove bottom cover following established procedures

Disconnect battery to ensure complete power isolation

Remove all visible screws securing palmrest assembly

Document screw locations and lengths for reassembly

Professional Disconnection :

Carefully disconnect touchpad ribbon cable from motherboard

Disconnect fingerprint reader cable if present

Remove any additional cables connected to palmrest

Note cable routing for proper reassembly

Palmrest Separation :

Use plastic pry tools to release retention clips

Start from front edge and work around perimeter

Lift palmrest assembly carefully to avoid cable damage

Set aside on clean, static-free surface

Keyboard Assembly Removal

Keyboard Retention :

Locate keyboard retention screws under palmrest area

Remove 4-6 Phillips #00 screws securing keyboard frame

Note screw lengths and locations for reassembly

Some models may have adhesive strips under keyboard

Professional Disconnection :

Carefully lift keyboard assembly at 30-degree angle

Locate keyboard ribbon cable connector on motherboard

Release locking mechanism (slide or flip type)

Gently pull ribbon cable straight out from connector

Keyboard Extraction :

Lift keyboard assembly completely from chassis

Check for any additional cables or connections

Inspect keyboard membrane and connector for damage

Clean keyboard bay area before installing replacement

🔌 Professional Membrane Repair Techniques

Common Membrane Issues :

Spill damage causing short circuits

Worn contact points from heavy use

Cracked or damaged membrane layers

Loose or corroded ribbon cable connections

Professional Repair Methods :

Use isopropyl alcohol to clean spill residue

Apply conductive paint for worn contact points

Replace ribbon cable with compatible replacement

Use membrane repair kits for minor damage

Test continuity with multimeter before reassembly

🔄 Professional Installation Process

New Keyboard Preparation :

Inspect new keyboard for any shipping damage

Verify ribbon cable length and connector type

Test keyboard functionality before installation if possible

Remove protective films from adhesive areas

Professional Connection :

Route ribbon cable through proper channels

Connect ribbon cable to motherboard connector

Secure locking mechanism (slide or flip into place)

Ensure cable is not pinched or overly tensioned

Keyboard Positioning :

Align keyboard with chassis mounting points

Lower keyboard into position evenly

Ensure all edges seat properly in chassis grooves

Verify no cables are trapped under keyboard

Final Assembly :

Install keyboard retention screws in proper sequence

Reconnect palmrest cables and secure assembly

Reinstall bottom cover and battery

Test all keyboard functions before final closure

💡 Professional Backlight Troubleshooting

Common Backlight Problems :

No backlight illumination

Inconsistent lighting across keyboard

Backlight flickering or intermittent operation

Color inconsistencies in RGB models

Professional Solutions :

Check Dell Quickset or Alienware Command Center settings

Update keyboard drivers and BIOS firmware

Test backlight functionality in BIOS settings

Check ribbon cable connection for backlight power

Verify backlight settings in Windows Mobility Center

🔧 Professional Troubleshooting Common Issues

Keys Not Responding :

Reseat ribbon cable connection firmly

Check for debris under non-responsive keys

Test keyboard in BIOS to isolate software issues

Update chipset and keyboard drivers from Dell

Check for physical damage to membrane or key switches

Ghost Key Presses :

Clean keyboard thoroughly with compressed air

Check for spill residue causing short circuits

Test with external keyboard to confirm issue

Inspect membrane for wear or damage points

Update BIOS to latest version from Dell Support

Backlight Not Working :

Check function key combinations (Fn + F10 typically)

Verify backlight settings in Dell Power Manager

Test in BIOS to confirm hardware functionality

Check ribbon cable connection for backlight circuit

Update keyboard firmware if available

📊 Professional Testing & Validation

Functional Testing :

Test every key using on-screen keyboard or testing software

Verify numeric keypad and function key operation

Test backlight functionality and brightness controls

Check special function keys (volume, brightness, etc.)

Verify spill resistance by testing drainage if applicable

Professional Application Testing :

CAD: Test common shortcut keys and macros

Programming: Test bracket, symbol, and navigation keys

Data Entry: Verify numeric keypad speed and accuracy

Gaming: Test simultaneous key presses and response

General: Test typing comfort and key travel consistency

💰 Enterprise Value Impact Analysis

Replacement Type

Cost Investment

Value Added

ROI Percentage

Professional Impact

Genuine Dell Premium

$80-$150

$120-$180

50-120%

Maximum professional appearance

Certified Refurbished

$40-$80

$80-$120

100-200%

Good professional quality

Third-Party Basic

$25-$60

$40-$80

60-160%

Functional but lower quality

Professional Repair

$15-$30

$60-$100

200-400%

Cost-effective for specific issues

🎯 Professional Replacement Recommendations

Enterprise Workstation :

Recommended: Dell Genuine Premium Keyboard

Optimal for: Professional offices, client-facing environments

Benefits: Full warranty, guaranteed compatibility

Features: Backlit, spill-resistant, premium feel

Field Engineering :

Recommended: Dell Certified Refurbished

Optimal for: Rugged environments, cost-conscious projects

Benefits: Reliable performance, significant cost savings

Features: Tested reliability, professional quality

Budget-Conscious Professional :

Recommended: Third-party compatible with good reviews

Optimal for: Personal workstations, secondary systems

Benefits: Lowest cost, functional replacement

Features: Basic functionality, variable quality

💡 Enterprise Quality Tip: For Dell Precision 7540 workstations used in professional environments, installing a genuine Dell Premium keyboard with backlighting can increase resale value by 20-25% and significantly enhance user productivity, as enterprise buyers highly value the professional appearance, reliable typing experience, and productivity benefits of quality keyboard components in mission-critical workstations.

8. Dell Precision 7540 Display Assembly & Professional Hinge Replacement

🖥️ Display Specifications & Professional Features

Technical Specifications :

15.6-inch display with multiple panel options

Full HD (1920x1080) IPS with 500 nits brightness

4K UHD (3840x2160) IPS with HDR400 support

Touch screen options available on select models

Dell PremierColor with 100% Adobe RGB coverage

Professional Compatibility Notes :

Verify Dell Parts Compatibility for exact model match

Different panel types require specific LCD cables

Hinge mechanisms vary by display size and weight

Touch and non-touch displays have different bezel designs

⚠️ Professional Safety Precautions

Complete shutdown and disconnect all power sources

Remove battery following established safety procedures

Use anti-static wrist strap throughout process

Work on padded surface to protect display during disassembly

Handle LCD panel with extreme care to prevent cracking

Document all cable routing and connector locations with photos

💡 Professional Display Replacement Options

Display Type

Professional Features

Cost Range

Installation Complexity

Enterprise Value

FHD IPS 500 nits

Anti-glare, 100% sRGB, PremierColor

$150-$250

Advanced

Good (+$200-$300)

4K UHD HDR400

100% Adobe RGB, HDR, Touch optional

$300-$500

Advanced

Premium (+$400-$600)

FHD Touch Screen

10-point touch, anti-smudge coating

$200-$350

Expert

Specialized (+$250-$400)

Refurbished OEM

Tested reliability, cost-effective

$100-$200

Advanced

Fair (+$150-$250)

🔧 Professional Display Disassembly Process

Display Bezel Removal

Initial Preparation :

Lay workstation on clean, padded surface

Open display to 90-degree angle for access

Use plastic pry tools to release bezel clips

Start from bottom edge near hinge area

Professional Clip Release :

Work around perimeter, releasing clips every 2 inches

Apply even pressure to prevent bezel damage

Listen for subtle clicks indicating clip release

Be careful around webcam and microphone areas

Bezel Separation :

Lift bezel away from display assembly carefully

Check for any adhesive strips or hidden screws

Set bezel aside on clean, static-free surface

Inspect bezel clips for damage during removal

LCD Panel Removal

LCD Mounting :

Locate 4-6 mounting screws around LCD perimeter

Remove screws securing LCD to display lid

Note screw lengths and locations for reassembly

Some models may have adhesive mounting strips

Professional Disconnection :

Carefully lift LCD panel at 30-degree angle

Locate LCD ribbon cable and backlight connector

Release locking mechanisms on both connectors

Gently pull cables straight out from connectors

Disconnect webcam and microphone cables if present

Panel Extraction :

Lift LCD panel completely from display assembly

Place panel on padded, static-free surface

Inspect connectors and cables for any damage

Clean display lid area before installing replacement

⚙️ Professional Hinge Replacement Process

Hinge Access :

Remove display back cover (metal lid assembly)

Locate hinge mounting points on display lid

Identify Torx T8 screws securing hinges to lid

Document hinge orientation for proper reassembly

Professional Removal :

Remove Torx T8 screws from hinge-to-lid connections

Carefully separate hinges from display lid

Note cable routing around hinge mechanisms

Inspect hinge barrels and mounting points for wear

Base Hinge Removal :

Access hinge mounting points from main chassis

Remove Phillips #00 screws securing hinges to base

Carefully extract hinge assemblies from chassis

Check for any hidden screws or retention clips

🔌 Professional Cable Routing & Management

Critical Cable Connections :

LCD ribbon cable (30-40 pin LVDS or eDP)

Backlight inverter or LED power cable

Webcam and microphone flex cables

Wi-Fi antenna cables (black and white)

Touch screen digitizer cable (if applicable)

Professional Routing Techniques :

Follow original cable routing paths exactly

Use cable guides and adhesive strips for securement

Ensure cables have proper slack for hinge movement

Avoid sharp bends or pinching points

Test cable movement through full hinge range

🔄 Professional Installation Process

New Component Preparation :

Inspect new display for any shipping damage

Verify hinge mechanism smoothness and alignment

Test display functionality before installation if possible

Check cable lengths and connector types match

Professional Hinge Installation :

Install new hinges into base chassis first

Secure with proper torque on mounting screws

Attach hinges to display lid with Torx T8 screws

Verify hinge alignment and smooth operation

Display Panel Installation :

Connect all cables to new LCD panel

Secure locking mechanisms on all connectors

Position LCD panel in display lid assembly

Install mounting screws in proper sequence

Verify panel is centered and properly seated

Final Assembly :

Route all cables through proper channels

Snap bezel back into place around perimeter

Test hinge operation through full range of motion

Connect power and test display functionality

Verify color accuracy and backlight uniformity

🔩 Professional Hinge Problem Diagnosis

Common Hinge Problems :

Loose hinge causing display wobble

Stiff hinge requiring excessive opening force

Broken hinge mounting points in chassis

Stripped hinge screw threads

Cracked display lid from hinge stress

Professional Solutions :

Replace complete hinge assembly for loose hinges

Lubricate hinge mechanism with appropriate grease

Use thread repair kits for stripped screw holes

Replace display lid for cracked or damaged units

Upgrade to heavy-duty hinges for frequent use

🔧 Professional Troubleshooting Common Issues

Display Not Working :

Reseat LCD ribbon cable connections firmly

Check backlight connector for proper engagement

Test with external display to isolate GPU issues

Update graphics drivers from Dell Support site

Check BIOS settings for display configuration

Backlight Issues :

Verify backlight cable connection and locking

Check backlight settings in Windows and BIOS

Test with known-good display panel

Update BIOS to latest version from Dell

Check for inverter board issues (older models)

Touch Screen Problems :

Reseat digitizer cable connection

Update touch screen drivers from Dell

Calibrate touch screen in Windows settings

Check for physical damage to digitizer layer

Test touch functionality in BIOS if available

📊 Professional Testing & Validation

Display Quality Testing :

Test for dead pixels using solid color backgrounds

Check backlight uniformity across entire display

Verify color accuracy with calibration tools

Test viewing angles and anti-glare performance

Check touch responsiveness across entire surface

Hinge Performance Testing :

Test hinge smoothness through full range of motion

Verify display stays in position at various angles

Check for any cable binding or tension issues

Test repeated open/close cycles for durability

Verify no creaking or grinding sounds during operation

💰 Enterprise Value Impact Analysis

Replacement Type

Cost Investment

Value Added

ROI Percentage

Professional Impact

FHD Premium Upgrade

$150-$250

$300-$450

100-200%

Excellent color accuracy for design work

4K UHD Upgrade

$300-$500

$500-$800

67-160%

Maximum resolution for detailed work

Hinge Replacement

$40-$80

$150-$250

275-525%

Restores professional appearance

Complete Assembly

$200-$400

$400-$700

100-250%

Like-new display and hinge performance

🎯 Professional Display & Hinge Recommendations

CAD & Engineering Workstation :

Recommended: FHD IPS 500 nits PremierColor

Optimal for: Technical drawings, 3D modeling

Benefits: Accurate colors, anti-glare, high brightness

Hinges: Standard replacement with proper tension

Media & Content Creation :

Recommended: 4K UHD HDR400 with 100% Adobe RGB

Optimal for: Photo editing, video production

Benefits: Maximum resolution, color accuracy

Hinges: Premium smooth-operation hinges

Field & Mobile Professional :

Recommended: FHD Touch Screen with reinforced hinges

Optimal for: Presentations, client demonstrations

Benefits: Interactive capability, durability

Hinges: Heavy-duty for frequent travel use

💡 Enterprise Quality Tip: For Dell Precision 7540 workstations, upgrading to a Dell PremierColor display with proper hinge replacement can increase resale value by 30-40% and significantly enhance professional productivity, as enterprise buyers highly value color-accurate displays for design work and robust hinge mechanisms that maintain their performance through years of daily use in demanding professional environments.

9. Dell Precision 7540 Cooling System Maintenance & Professional Thermal Paste Application

❄️ Cooling System Specifications & Professional Features

Technical Specifications :

Dual-fan cooling system with independent heat pipes

CPU cooling: Dual heat pipes with 47+ fins

GPU cooling: Dual heat pipes with 55+ fins (discrete models)

Dell Advanced Thermal Management framework

Intelligent fan control with multiple performance profiles

Professional Performance Notes :

Supports Intel Xeon and Core i9 processors up to 45W TDP

Optimized for professional graphics (NVIDIA Quadro/AMD Radeon Pro)

Dell Power Manager integration for thermal profiles

Dust-reduction technology with strategically placed vents

⚠️ Professional Safety Precautions

Complete shutdown and disconnect all power sources

Remove battery following established safety procedures

Allow system to cool completely before disassembly

Use anti-static wrist strap throughout process

Work on clean, static-free professional service surface

Handle heat pipes and fins with care to avoid damage

🧴 Professional Thermal Material Selection

Thermal Compound

Professional Benefits

Thermal Conductivity

Application Difficulty

Enterprise Reliability

Arctic MX-6

Excellent longevity, non-conductive

10.6 W/mK

Easy

Outstanding (8+ years)

Thermal Grizzly Kryonaut

Maximum performance, high-end

12.5 W/mK

Medium

Excellent (5-7 years)

Noctua NT-H2

Reliable, easy application

8.9 W/mK

Easy

Excellent (6+ years)

Prolimatech PK-3

Professional grade, non-capacitive

11.2 W/mK

Medium

Outstanding (7+ years)

🔧 Professional Cooling System Disassembly

Heat Sink Assembly Removal

Initial Preparation :

Remove bottom cover following established procedures

Disconnect battery to ensure complete power isolation

Remove all visible screws securing heat sink assembly

Document screw locations and lengths for reassembly

Professional Disconnection :

Carefully disconnect CPU and GPU fan power cables

Note cable routing for proper reassembly

Identify heat sink mounting screw sequence (typically numbered)

Loosen screws in reverse numerical order (8-7-6-5-4-3-2-1)

Heat Sink Separation :

Gently twist heat sink to break thermal compound seal

Lift heat sink assembly straight up to avoid damage

Inspect thermal pads on VRMs and memory chips

Clean old thermal compound from CPU and GPU dies

Fan Assembly Maintenance

Fan Removal :

Remove screws securing fan assemblies to chassis

Disconnect fan power cables from motherboard

Carefully lift fan assemblies from mounting points

Note orientation and cable routing for reassembly

Professional Cleaning :

Use compressed air to remove dust from fan blades

Clean fan vents and heat sink fins thoroughly

Check fan bearings for wear or noise issues

Lubricate fan bearings if accessible and necessary

🎯 Professional Thermal Paste Application Techniques

Surface Preparation

Cleaning Process :

Use 99% isopropyl alcohol and lint-free cloths

Clean both CPU/GPU dies and heat sink surfaces

Remove all old thermal compound completely

Ensure surfaces are completely dry before application

Professional Inspection :

Check CPU and GPU dies for scratches or damage

Inspect heat sink base for flatness and condition

Verify thermal pad thickness and condition

Replace damaged thermal pads with correct thickness

Professional Application Methods

Pea Method (Recommended) :

Apply rice-sized dot in center of CPU die

Use slightly larger dot for GPU die

Pressure from heat sink spreads compound evenly

Ideal for most professional applications

Spread Method (Advanced) :

Use plastic applicator to spread thin, even layer

Ensure complete coverage without excess

Recommended for liquid metal compounds only

Requires professional experience

X Method (Alternative) :

Draw thin X pattern across CPU/GPU dies

Effective for larger die surfaces

Ensures corner coverage

Good for high-performance applications

📏 Professional Thermal Pad Management

Critical Pad Locations :

VRM power stages (typically 1.0mm thickness)

GPU memory chips (typically 0.5mm-1.0mm)

PCH chipset (typically 0.5mm)

VRAM modules (typically 1.0mm)

Professional Replacement Guidelines :

Measure original pad thickness with calipers

Use high-conductivity thermal pads (6.0 W/mK+)

Ensure proper compression without excessive force

Cut pads slightly larger than components for coverage

Remove protective films from both sides before installation

🔄 Professional Reassembly Process

Heat Sink Installation :

Apply thermal paste using preferred method

Position heat sink assembly over CPU and GPU

Align screw holes and lower heat sink gently

Install screws in numerical sequence (1-2-3-4-5-6-7-8)

Use proper torque - snug but not overtightened

Fan Assembly Installation :

Position fan assemblies in chassis mounts

Secure with appropriate screws

Connect fan power cables to motherboard

Ensure proper cable routing to avoid interference

Final Verification :

Verify all connections are secure

Check that no cables are pinched

Ensure heat sink makes full contact with dies

Test fan operation before final closure

🔧 Professional Troubleshooting Common Issues

Overheating Problems :

Check thermal paste application and coverage

Verify heat sink mounting pressure and flatness

Clean dust from vents and heat sink fins

Update BIOS and Dell Power Manager

Test with different thermal performance profiles

Fan Noise Issues :

Clean fan blades and bearings

Check for cable interference with fan blades

Update BIOS for improved fan control algorithms

Replace worn fan bearings if necessary

Adjust fan curves in Dell Power Manager

Performance Throttling :

Monitor temperatures with HWiNFO

Check power limits and thermal throttling flags

Verify adequate ventilation during heavy workloads

Consider laptop cooling pad for additional airflow

Repaste with higher performance thermal compound

📊 Professional Thermal Testing & Validation

Stress Testing Tools :

Run Prime95 for CPU thermal testing

Use 3DMark for GPU thermal validation

Monitor temperatures with HWiNFO or Core Temp

Test with professional applications (CAD, rendering)

Validate fan curves and acoustic performance

Performance Benchmarking :

Record idle and load temperatures

Measure thermal throttling occurrences

Document fan noise levels at various speeds

Compare before/after thermal performance

Validate sustained performance under load

💰 Enterprise Value Impact Analysis

Thermal Service

Cost Investment

Value Added

ROI Percentage

Professional Benefit

Professional Repaste

$20-$40

$100-$180

400-800%

Maximum performance restoration

Complete Cleaning

$15-$25

$80-$140

430-840%

Improved cooling and reliability

Fan Replacement

$40-$70

$90-$150

125-275%

Quiet operation and cooling capacity

Thermal Pad Upgrade

$25-$45

$70-$120

180-380%

Enhanced VRM and memory cooling

📅 Professional Maintenance Schedule

Routine Maintenance (Every 6-12 months) :

Dust cleaning of vents and fans

Visual inspection of cooling system

Performance validation under load

Fan bearing noise assessment

Comprehensive Service (Every 2-3 years) :

Complete disassembly and cleaning

Thermal paste replacement

Thermal pad inspection and replacement

Fan performance testing and replacement if needed

🎯 Professional Thermal Management Recommendations

High-Performance Workstation :

Thermal Compound: Thermal Grizzly Kryonaut

Thermal Pads: Gelid GP-Extreme 6.0 W/mK

Maintenance: Quarterly cleaning, annual repaste

Power Setting: Ultra Performance in Dell Power Manager

Balanced Professional Use :

Thermal Compound: Arctic MX-6

Thermal Pads: Arctic Thermal Pad 6.0 W/mK

Maintenance: Semi-annual cleaning, biennial repaste

Power Setting: Optimized in Dell Power Manager

Quiet Office Environment :

Thermal Compound: Noctua NT-H2

Thermal Pads: Standard replacement pads

Maintenance: Annual cleaning as needed

Power Setting: Quiet in Dell Power Manager

💡 Enterprise Performance Tip: Regular professional thermal maintenance on Dell Precision 7540 workstations can increase sustained performance by 15-25% and boost resale value by 20-30%, as enterprise buyers highly value workstations that maintain optimal thermal performance for demanding professional applications like CAD, rendering, and scientific computing where thermal throttling can significantly impact productivity.

10. Where to Sell Your Dell Precision 7540 for Maximum Profit

📊 Current Dell Precision 7540 Market Analysis

2024 Professional Workstation Demand :

Strong demand from engineering firms and CAD professionals

Growing interest from educational institutions for STEM programs

Small businesses seeking cost-effective workstation solutions

Remote workers upgrading home office setups

Pricing Trends :

Base models (Core i5, 8GB RAM): $600-$800

Mid-range (Core i7, 16GB RAM, Quadro): $900-$1,200

High-end (Xeon, 32GB+ RAM, RTX): $1,300-$1,800

Fully upgraded (128GB RAM, dual SSD): $1,800-$2,400

🛒 Mainstream Marketplace Options

Platform

Professional Advantage

Fee Structure

Average Sale Price

Time to Sell

eBay

Global reach, auction format

12.9% + $0.30

Market value +10%

3-10 days

Facebook Marketplace

Local sales, no fees

0%

Market value -15%

1-14 days

Craigslist

Local professionals

0%

Market value -20%

7-21 days

OfferUp

Mobile-friendly, local

0%

Market value -18%

5-14 days

💰 Professional Pricing Strategy

Value-Added Pricing Factors :

Recent thermal paste application: +$80-$120

SSD upgrade with fresh OS: +$100-$150

RAM upgrades to 32GB+: +$150-$300

Professional calibration documentation: +$50-$80

Original packaging and accessories: +$60-$100

Market Positioning :

Premium pricing for CAD-ready configurations

Competitive pricing for general business use

Bundle pricing with accessories and software

Seasonal pricing adjustments (back-to-school, year-end)

📈 Professional Listing Optimization

Keyword Strategy :

Primary: "Dell Precision 7540 workstation"

Secondary: "CAD laptop", "engineering computer"

Tertiary: "ISV certified", "SolidWorks ready"

Features: "Xeon processor", "Quadro graphics"

Professional Photography :

High-resolution images from all angles

Close-ups of professional features and ports

Photos showing display quality and color accuracy

Documentation of upgrades and maintenance

⏰ Optimal Selling Timing

Seasonal Opportunities :

January-February: Business budget refresh cycles

August-September: Back-to-school and academic year

April-May: End of fiscal year for corporations

November-December: Year-end budget spending

Market Timing :

List on Tuesday-Wednesday for maximum visibility

End auctions on Sunday evening for highest bids

Avoid holiday weekends and major events

Monitor competitor pricing and adjust accordingly

🎯 Professional Presentation Tips

Documentation Package :

Include Dell service tag and warranty information

Provide benchmark results and performance metrics

Document all upgrades and maintenance performed

Include original purchase receipt if available

Professional Cleaning :

Thorough external cleaning and sanitization

Keyboard and screen deep cleaning

Port cleaning and inspection

Fresh Windows installation with latest drivers

📦 Professional Shipping & Packaging

Secure Packaging :

Use original Dell packaging if available

Double-box with adequate padding

Include silica gel packs for moisture control

Use "Fragile" and "This Side Up" labels

Shipping Insurance :

Always insure for full replacement value

Use signature confirmation for high-value items

Photograph packaging process for insurance claims

Choose reputable carriers with tracking

💼 Maximizing Enterprise Buyer Appeal

Business-Focused Features :

Highlight ISV certifications and compatibility

Emphasize professional graphics capabilities

Showcase upgrade potential and serviceability

Document thermal management and cooling performance

Professional Assurance :

Offer short-term technical support

Provide detailed specifications and benchmarks

Include professional application performance data

Offer business invoice for tax purposes

🛡️ Professional Risk Management

Payment Security :

Use PayPal Goods & Services for protection

Wait for payments to clear before shipping

Verify buyer profiles and feedback ratings

Use escrow services for high-value transactions

Documentation :

Keep records of all communications

Photograph item condition before shipping

Save tracking numbers and shipping receipts

Maintain serial number records

⚡ Quick Sale Strategies

Instant Buyers :

SellBroke : Immediate quotes, fast paymentSellLaptopBack : Quick evaluation processGazelle: Competitive for business laptops

Best Buy Trade-In: Convenient but lower offers

Local Options :

Computer repair shops specializing in workstations

Local IT companies seeking used equipment

University surplus stores

Engineering and architectural firms

💡 Maximum Profit Tip: For Dell Precision 7540 workstations, combining SellBroke's professional buyer network with detailed documentation of upgrades and professional maintenance can yield 20-30% higher returns than standard marketplaces. Enterprise buyers on specialized platforms understand the value of properly maintained workstation equipment and pay premiums for documented performance and reliability.

Need to Sell Your Dell Laptop? Get Instant Cash!

If your Dell Precision 7540 (or other Precision mobile workstation) has performance issues or you're upgrading to a newer model, we offer premium cash payouts for your device. We buy broken, used, and refurbished Dell Precision workstations—including all 7540 configurations—with free insured shipping and hassle-free evaluations.

Sell Popular Dell Models Now: