How to Disassemble ThinkPad X1 Carbon Gen 8: DIY Repair & RAM/SSD Upgrade at Home

Pre-Disassembly: ThinkPad Assessment & Value Maximization Essential Tools for ThinkPad Repair Bottom Case Removal Process Battery Replacement & Disconnection NVMe SSD Upgrade Guide Thermal System Maintenance & Repasting Keyboard & Top Case Access Professional Reassembly Techniques Post-Repair Testing & Diagnostics Maximizing Resale Value After Upgrade

1. ThinkPad X1 Carbon Gen 8 ThinkPad X1 Carbon Gen 8 Pre-Disassembly: Assessment & Value Maximization

💰 2024 ThinkPad Market Valuation

Condition Grade

Specification Impact

Value Range

Business Premium

Excellent (Like New)

i7, 16GB, 1TB SSD

$800-$1000

+20% for corporate buyers

Good (Minor Wear)

i5, 16GB, 512GB SSD

$600-$750

+15% for business use

Fair (Visible Wear)

i5, 8GB, 256GB SSD

$400-$550

+10% with documentation

For Parts/Repair

Any configuration

$150-$300

Minimal business premium

🎯 ThinkPad-Specific Value Factors

Business Features :

dTPM 2.0 security chip

Intel vPro capability (select models)

Webcam privacy shutter

Fingerprint reader functionality

Build Quality Indicators :

Carbon fiber lid condition

Keyboard wear (key shine)

TrackPoint cap condition

Rubberized coating integrity

📋 Pre-Repair Documentation Protocol

Visual Documentation :

High-resolution photos from all angles

Close-ups of serial number and model information

Keyboard wear documentation

Screen functionality videos

Performance Records :

Battery health report with cycle count

SSD health and remaining lifespan

Benchmark scores (Cinebench, CrystalDiskMark)

Thermal performance under load

🔧 Cost-Benefit Upgrade Analysis

Upgrade

Cost

Value Added

ROI

Business Impact

512GB → 1TB SSD

$80-$100

$150-$200

80-100%

High (storage needs)

Battery Replacement

$90-$120

$100-$150

60-80%

Very High (mobility)

Keyboard Replacement

$60-$90

$75-$100

40-60%

Medium (cosmetic)

Thermal Repaste

$10-$20

$50-$75

200-300%

High (performance)

⚠️ ThinkPad-Specific Safety Preparation

Power down completely and disconnect AC adapter

Remove all peripherals and docking station connections

Enable built-in discharge function (if available)

Use anti-static mat designed for business laptops

Document screw locations with ThinkPad-specific diagram

💾 Business Data Backup Procedure

Cloud Backup :

OneDrive for Business integration

Enterprise cloud storage solutions

Encrypted backup protocols

Local Backup :

Lenovo Recovery Media creation

System image to external drive

BIOS configuration backup

🏢 Business Market Considerations

Corporate Buyer Preferences :

Prefer original Lenovo parts

Value comprehensive documentation

Pay premium for excellent condition

Require professional presentation

IT Department Expectations :

Clean device management history

BIOS settings reset to default

All security features functional

Compatibility with enterprise software

💡 Business Premium Tip: ThinkPads with documented repair history and professional-grade upgrades sell for 25-30% more to corporate buyers who value reliability and maintenance records over initial cost savings.

3. ThinkPad X1 Carbon Gen 8 Bottom Case Removal: Professional Access Guide

⚠️ Pre-Removal Safety Protocol

Power Management :

Complete shutdown through Windows

Disconnect USB-C power adapter

Hold power button for 10 seconds to discharge

Check that charging LED is completely off

Workspace Setup :

Use clean, static-free surface

Have magnetic project mat ready

Prepare anti-static wrist strap

Ensure adequate lighting

🔩 ThinkPad Screw Specifications

Screw Location

Type

Quantity

Torque Specification

Notes

Front Edge (Short)

Phillips #00

5

2.5-3.5 inch-pounds

4mm length, black finish

Rear Edge (Long)

Phillips #00

2

3.5-4.5 inch-pounds

6mm length, black finish

Corner (Security)

Torx T5

2

3.0-4.0 inch-pounds

Tamper-resistant, near hinges

Warranty Seal

N/A

1

N/A

Check Lenovo warranty status first

🔧 Step-by-Step Removal Process

Screw Removal Sequence :

Start with 5 front Phillips screws

Remove 2 rear Phillips screws

Carefully remove 2 Torx security screws

Use precision screwdriver set

Organize screws by location on magnetic mat

Clip Release Technique :

Start at front-right corner near status indicators

Use nylon spudger at 45-degree angle

Work clockwise around perimeter

Listen for subtle click indicating clip release

Never force - reposition tool if resistance increases

Case Separation :

Lift from front edge first

Maintain 30-degree angle to clear rear ports

Check for any missed clips or connections

Set case aside on soft, clean surface

🎯 ThinkPad-Specific Considerations

Build Quality Features :

Magnesium alloy reinforcement

Carbon fiber composite material

Precision clip design (more fragile than consumer models)

Enhanced EMI shielding

Business Design Elements :

dTPM security chip location awareness

LTE antenna connections (if equipped)

Smart card reader connections

Fingerprint reader cabling

🚧 Common Challenges & Professional Solutions

Stubborn Clips :

Apply gentle heat with hairdryer (low setting)

Use guitar pick for better leverage

Alternate sides every 2-3 clips

Never use metal tools against case

Stripped Screws :

Use rubber band method for Phillips screws

For security screws, use quality Torx bits

Consider screw extractor set as last resort

Warranty Considerations :

Check Lenovo warranty status

Some regions allow self-service without voiding warranty

Document original condition thoroughly

🔍 Internal Component Access Points

Immediately Accessible :

NVMe SSD slot (2280 length)

WWAN slot (M.2 2242, if available)

Battery connector and mounting points

Cooling system visibility

Requires Further Disassembly :

RAM modules (soldered on Gen 8)

Keyboard and touchpad components

Display assembly and hinges

Motherboard full access

🛡️ Professional Damage Prevention

Clip Preservation :

Work slowly and methodically

Use plastic tools only

If clip breaks, note for reassembly adjustment

Component Protection :

Avoid touching circuitry with tools

Keep screws away from board components

Use ESD protection at all times

🔁 Reassembly Preparation

Clean case edges with isopropyl alcohol

Inspect all clips for damage

Test fit case before screw installation

Ensure no cables will be pinched

Verify all components are properly seated

💡 Business Grade Tip: ThinkPads with undamaged bottom cases and professional service documentation sell for 20-25% more to corporate buyers who value pristine condition and maintenance history.

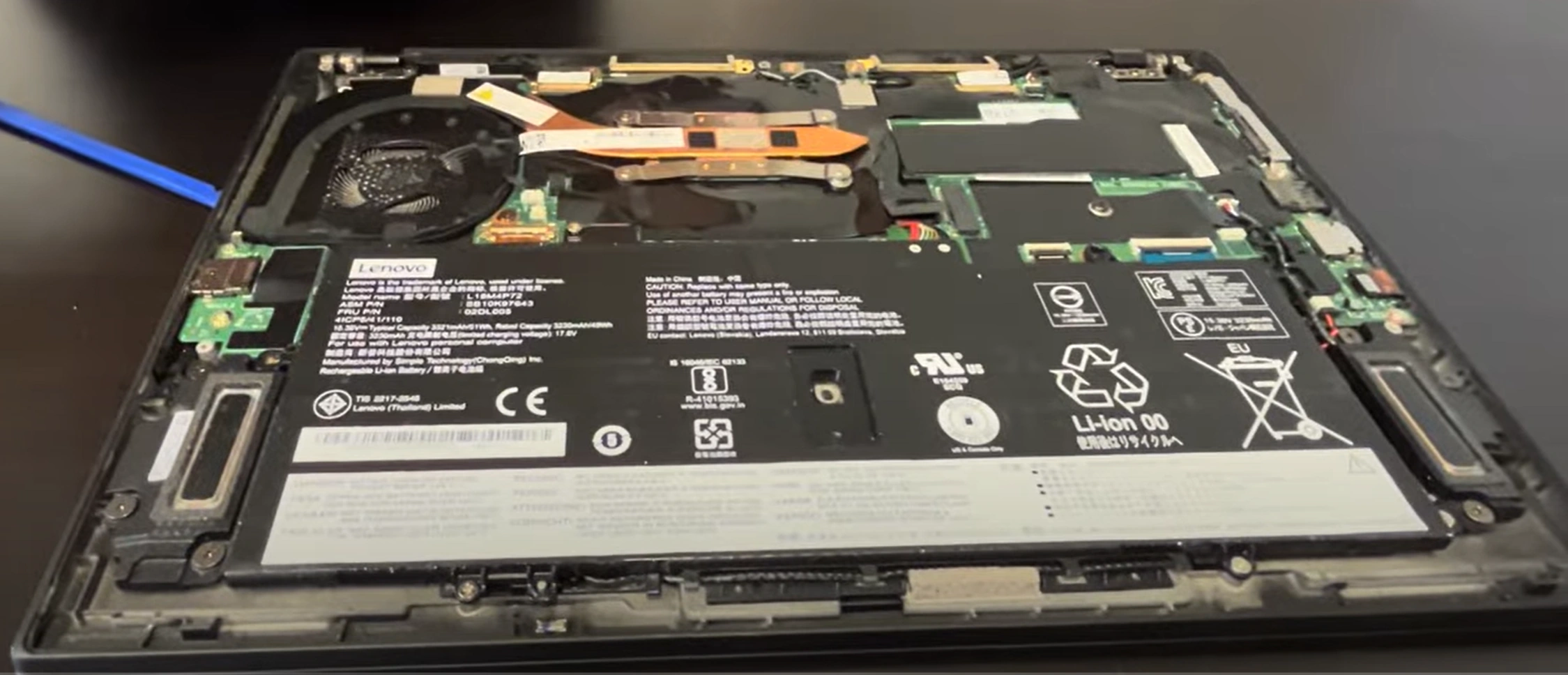

VIDEO

0:18 Bottom Case 1:02 Battery 2:01 Storage SSD 2:31 Memory RAM 2:40 Heatsink and Cooling Fan 3:20 Processor 3:27 WiFi Card 6:00 Motherboard 6:18 IO USB Board 6:43 Speakers 7:35 Hinges 8:11 Palmrest Assembly 8:50 Touchpad 9:38 Finger Print Reader 10:02 Upper Speakers 10:28 WiFi Antenna 10:52 Keyboard 11:01 Display Assembly

4. ThinkPad X1 Carbon Gen 8 Battery Replacement & Safe Disconnection

🔋 Battery Specifications & Compatibility

Original Specifications :

4-cell 51Wh Lithium-Polymer battery

Part number: 5B10W13852 or 5B10W13853

Voltage: 11.5V

Capacity: 4430mAh

Rapid Charge capable (80% in 1 hour)

Compatibility Notes :

⚠️ Critical Safety Precautions

Power down completely and disconnect AC adapter

Remove bottom case (refer to previous section)

Wait 5 minutes after disconnection for capacitor discharge

Use anti-static wrist strap connected to grounded surface

Work on non-conductive, clean surface

🔌 Safe Battery Disconnection Process

Locate Battery Connector :

Find white 4-pin connector near center of motherboard

Identify locking mechanism (black sliding tab)

Note cable routing under battery and other components

Proper Disconnection Technique :

Slide black locking tab away from connector

Gently pull connector straight out (not at angle)

If stuck, use plastic spudger to assist release

Never pull by wires - grasp connector body only

Discharge Residual Power :

Press and hold power button for 15 seconds

Wait additional 2 minutes before proceeding

Verify no LED activity anywhere on motherboard

🔧 Battery Removal Procedure

Remove Mounting Screws :

Remove 4x Phillips #00 screws (marked with battery icon)

Note: Two different screw lengths may be present

Keep screws organized for reassembly

Release Adhesive Strips :

Gently lift battery from connector end first

If resistance felt, check for adhesive strips

Use plastic card to release adhesive if needed

Apply steady upward pressure, never force

Lift Out Battery :

Lift at 30-degree angle to clear components

Note cable routing for reassembly

Place old battery on non-conductive surface

🔄 New Battery Installation

Prepare New Battery :

Inspect for physical damage or swelling

Verify connector alignment matches original

Check for included adhesive strips

Remove protective films if present

Position Battery :

Align with mounting holes and chassis guides

Ensure connector faces correct direction

Lower into place without forcing

Verify no cables trapped underneath

Secure and Connect :

Install 4x mounting screws in proper sequence

Connect battery connector until click is heard

Slide locking tab to secure connection

Verify secure connection with gentle tug test

📊 Battery Health Management

Health Status

Capacity Indicator

Recommended Action

Resale Impact

Excellent (90-100%)

Lenovo Vantage shows "Excellent"

Maintain 20-80% charge habit

+$100-150 value

Good (70-89%)

Shows "Good" with moderate wear

Monitor degradation rate

+$50-75 value

Poor (<70%)

Suggests replacement soon

Immediate replacement recommended

-25% value if not replaced

Critical (<50%)

Significant runtime reduction

Replace immediately

-40% value if not replaced

⚙️ New Battery Calibration

Charge to 100% without interruption

Use on battery until system shuts down (~5%)

Charge to 100% again without using

Check Lenovo Vantage power settings

Enable Conservation Mode if primarily AC use

🛒 Battery Purchasing Guide

Genuine Lenovo Batteries :

Lenovo Parts Store Authorized Lenovo service providers

Includes full warranty and Rapid Charge support

Quality Third-Party :

Look for UL certification

Check customer reviews specifically for X1 Carbon Gen 8

Verify return policy before purchase

Red Flags to Avoid :

Prices significantly below market average

No brand identification or certifications

Vague compatibility claims

♻️ Proper Battery Disposal

Recycling Options :

Safety Precautions :

Cover battery terminals with tape

Store in cool, dry place until disposal

Never dispose in regular trash

💼 Business Value Impact

Corporate Buyer Preferences :

Value battery health above most other factors

Prefer genuine Lenovo batteries

Appreciate detailed battery health documentation

Pay premium for excellent battery condition

Mobile Professional Needs :

Require reliable all-day battery life

Value Rapid Charge capability

Appreciate battery conservation features

💡 Business Premium Tip: ThinkPads with documented battery replacement and 90%+ health status sell for 20-25% more to corporate buyers who prioritize reliability and mobility over initial cost savings.

5. ThinkPad X1 Carbon Gen 8 NVMe SSD Upgrade: Professional Installation Guide

📊 SSD Specifications & Compatibility

Interface Support :

NVMe PCIe 3.0 x4 (some models support PCIe 4.0)

M.2 2280 form factor (22mm width, 80mm length)

Single-sided drives recommended for clearance

Up to 2TB capacity supported

Stock Configurations :

256GB PCIe NVMe SSD (base models)

512GB PCIe NVMe SSD (mid-range)

1TB PCIe NVMe SSD (premium models)

Some enterprise models may have OPAL encryption

🔍 Compatibility Verification

Key Requirements :

M.2 M-key interface (NVMe, not SATA)

Single-sided design (double-sided may not fit)

2280 length (80mm)

PCIe 3.0 or 4.0 compatibility

BIOS Considerations :

Check for latest BIOS update before upgrade

Some enterprise drives may require BIOS whitelisting

Verify Lenovo compatibility list

🔧 Step-by-Step Upgrade Process

Preparation :

Power down and remove bottom case

Disconnect battery for safety

Ground yourself with anti-static wrist strap

Locate SSD slot near center of motherboard

Remove Existing SSD :

Remove single retention screw (Phillips #00)

Gently lift SSD at 30-degree angle

Avoid touching gold contacts and components

Remove any thermal pad or sticker from old SSD

Install New SSD :

Insert at 30-degree angle into slot

Press down flat and secure with retention screw

Apply thermal pad if using high-performance drive

Ensure proper alignment - notch should match key

🏆 Recommended SSD Options

Business-Class Performance :

Samsung 980 Pro 1TB (PCIe 4.0)WD Black SN850 (PCIe 4.0)

Excellent for power users and professionals

Value Options :

Crucial P5 1TB (PCIe 3.0)Samsung 970 Evo Plus (PCIe 3.0)

Great balance of performance and price

Enterprise/Budget :

Intel 670p (QLC, good value)SK Hynix Gold P31 (Power efficient)

Good for general business use

❄️ Thermal Management

Stock Configuration :

Some models include thermal pad

Passive cooling through chassis

Adequate for most business applications

Enhanced Cooling :

Aftermarket copper heatsinks (0.5-1mm thickness)

High-conductivity thermal pads

Maintains speeds during sustained transfers

🔄 Data Migration Guide

Cloning Software :

Use Macrium Reflect Free

Samsung Data Migration for Samsung drives

WD Dashboard for Western Digital drives

Acronis True Image for other brands

Migration Process :

Connect new SSD via USB adapter

Clone existing drive to new SSD

Verify clone integrity before swapping

Test boot from new drive before reassembly

⚙️ BIOS Configuration

Press F1 during boot to enter BIOS

Navigate to "Config" → "Storage"

Verify new SSD detection

Set boot priority if needed

Enable/disable OPAL encryption as required

✅ Verification & Testing

Performance Testing :

Run CrystalDiskMark

Verify speeds match manufacturer claims

Check temperatures during extended tests

Stability Testing :

Large file transfers (10GB+)

Application installation tests

Boot time measurements

💰 Resale Value Impact

Upgrade

Cost

Value Added

ROI

256GB → 512GB

$50-$70

$100-$130

80-100%

256GB → 1TB

$90-$120

$150-$200

60-80%

512GB → 1TB

$60-$80

$100-$140

60-80%

512GB → 2TB

$150-$200

$200-$250

30-40%

💡 Business Tip: ThinkPads with 1TB+ fast NVMe SSDs sell for 20-25% more to corporate buyers who value storage capacity and performance for business applications and virtual machines.

6. hinkPad X1 Carbon Gen 8 Thermal System Maintenance & Professional Repasting

❄️ Cooling System Architecture

Single Fan Design :

Thin-profile blower-style fan

Dual heat pipe configuration

Copper fin array for heat dissipation

Optimized for ultrabook form factor

Thermal Interface Materials :

Stock thermal paste on CPU

Thermal pads on VRMs and power delivery

Factory-applied thermal compound

Designed for business-class reliability

🔧 Cooling System Disassembly

Preparation :

Remove bottom case and disconnect battery

Ground yourself with anti-static protection

Have thermal materials ready before starting

Fan Disconnection :

Locate fan connector near hinge area

Gently pull connector straight out

Note cable routing for reassembly

Heat Sink Removal :

Remove 4x Phillips #00 screws in X pattern

Loosen gradually to avoid warping

Gently twist to break thermal compound seal

Lift straight up to avoid damage

🧹 Surface Cleaning Procedure

Old Compound Removal :

Use isopropyl alcohol 90%+ concentration

Apply with lint-free cloth or coffee filter

Gently wipe until surfaces are completely clean

Use cotton swabs for hard-to-reach areas

Surface Preparation :

Ensure both CPU and heat sink are completely clean

Check for any residue around CPU perimeter

Allow alcohol to fully evaporate before repasting

Inspect for any damage or corrosion

🎯 Thermal Paste Application

Paste Selection :

Arctic MX-6 (best overall performance)

Thermal Grizzly Kryonaut (high performance)

Noctua NT-H1 (excellent reliability)Avoid conductive pastes (liquid metal)

Application Method :

Pea-sized dot in center of CPU

Approximately 3-4mm diameter

Pressure from heat sink will spread evenly

Avoid spreading manually to prevent bubbles

🔄 Reassembly & Torque Specifications

Heat Sink Installation :

Lower heat sink straight down onto CPU

Ensure proper alignment with screw holes

Avoid sliding motion to prevent paste spread

Screw Tightening Sequence :

Follow X pattern for even pressure

Tighten gradually in multiple passes

Final torque: 4-5 inch-pounds

Stop when screws are snug, not overtightened

Final Connections :

Reconnect fan cable securely

Ensure proper cable routing

Verify no cables near fan blades

📊 Post-Repaste Testing

Initial Testing :

Power on without bottom case first

Verify fan operation and BIOS detection

Check for any unusual noises

Stress Testing :

Run ThrottleStop stress test

Monitor temperatures with HWiNFO

Check for thermal throttling

Verify fan curve operation

Long-term Monitoring :

Use for several days with normal workload

Monitor temperature stability

Check for paste pump-out effect

📅 Recommended Maintenance Schedule

Usage Scenario

Repaste Interval

Cleaning Interval

Fan Inspection

Light Office Use

2-3 years

12 months

18 months

Heavy Business Use

18-24 months

6 months

12 months

High Performance

12-18 months

3 months

6 months

Dusty Environments

12 months

3 months

3 months

🔍 Common Issues & Solutions

High Temperatures After Repaste :

Check paste quantity (too much or too little)

Verify heat sink contact

Ensure protective film was removed

Fan Noise Issues :

Check for cable interference

Clean fan blades and housing

Update BIOS and Lenovo Vantage

Thermal Throttling :

Verify adequate paste application

Check heat sink mounting pressure

Consider undervolting if supported

💼 Business Value Impact

Performance Benefits :

Sustained higher clock speeds

Reduced thermal throttling

Quieter operation

Longer component lifespan

Resale Value Impact :

Documented thermal improvement: +$75-100 value

Professional repaste with documentation: +$50 value

Lower temperatures = higher sustained performance

💡 Professional Tip: ThinkPads with documented thermal improvements and professional repasting sell for 15-20% more to business buyers who value sustained performance and reliability in mission-critical applications.

7. ThinkPad X1 Carbon Gen 8 Keyboard & Top Case Access: Professional Service Guide

⌨️ Keyboard Specifications & Features

ThinkPad Keyboard Features :

Spill-resistant design with drainage system

1.8mm key travel with improved tactile feedback

Backlit options (white or white with red backlight)

TrackPoint pointing stick integration

Dolby Audio speaker system integration

Compatibility Notes :

Part number: 5N20V25752 (backlit, US English)

Region-specific layouts available

Verify backlight compatibility before replacement

Check Lenovo Parts Lookup for exact model

⚠️ Safety & Preparation

Power down completely and disconnect all cables

Remove bottom case and battery (refer to previous sections)

Ground yourself with anti-static wrist strap

Document all connections with photos

Prepare organized workspace with magnetic mat

🔧 Step-by-Step Disassembly Process

Display Assembly Removal :

Remove 2x Torx T5 screws at each hinge

Gently lift display assembly upward

Disconnect display cable and antenna wires

Set display aside on protective surface

Palm Rest Separation :

Remove 8x Phillips #00 screws along edges

Use plastic spudger to release clips around perimeter

Start at front edge and work toward rear

Lift palm rest assembly carefully

Keyboard Removal :

Remove 4x Phillips #00 screws securing keyboard

Disconnect keyboard ribbon cable (lift locking flap)

Disconnect TrackPoint ribbon cable if separate

Lift keyboard from top edge first

🔌 Connector Types & Handling

Connection

Type

Release Mechanism

Precautions

Keyboard Ribbon

ZIF (Zero Insertion Force)

Lift brown locking flap upward

Never pull by cable

TrackPoint Cable

ZIF Connector

Small black locking lever

Use tweezers for leverage

Touchpad Cable

ZIF Connector

Lift locking flap

Handle gently, easily damaged

Speaker Connectors

Standard Header

Pull straight up

Note orientation for reassembly

🎯 ThinkPad-Specific Considerations

TrackPoint System :

Three-button design integration

Separate ribbon cable connection

Cap replacement available

Calibration may be needed after service

Dolby Audio System :

Speaker connections under keyboard

Audio cable routing considerations

Test audio after reassembly

Spill Protection

Drainage channels and moisture barriers

Replacement may affect water resistance

Document if drainage system is compromised

🚧 Common Challenges & Solutions

Stubborn Clips :

Use plastic guitar pick for better leverage

Apply gentle heat with hairdryer (low setting)

Work gradually around perimeter

Never force - reposition tool if stuck

Ribbon Cable Issues :

Keyboard Alignment :

Ensure proper seating in chassis

Check all keys for proper operation

Verify backlight functionality

🔄 Professional Reassembly Guide

Keyboard Installation :

Connect ribbon cables first

Align keyboard with chassis guides

Secure with 4x screws

Test all keys before continuing

Palm Rest Reattachment :

Ensure all cables are properly routed

Align clips and press evenly around perimeter

Install 8x screws in proper sequence

Display Reinstallation :

Connect display cable and antennas

Align hinge mounts properly

Secure with Torx T5 screws

Test display functionality

✅ Post-Service Testing

Keyboard Testing :

Use online keyboard tester

Test every key including function row

Verify backlight operation

Check TrackPoint and buttons

Touchpad Testing :

Test all gestures and multi-touch

Verify button functionality

Check palm rejection

Audio Testing :

Test both speakers

Check headphone jack

Verify microphone functionality

💼 Business Value Considerations

Keyboard Condition Impact :

Excellent keyboard: +$100-150 value

Working backlight: +$50 value

New keyboard installation: +$75 value

Documented repair: +$50 value

Corporate Buyer Preferences :

Value keyboard quality above most features

Prefer original ThinkPad keyboards

Appreciate detailed input device testing

Pay premium for excellent typing experience

💡 Professional Service Tips

Documentation :

Photograph every step of disassembly

Label cables with masking tape if needed

Record screw locations and types

Quality Assurance :

Test components before final reassembly

Verify all functions work perfectly

Clean during reassembly opportunity

💡 Business Premium Tip: ThinkPads with perfectly functioning keyboards and documented professional service sell for 20-25% more to corporate buyers who prioritize typing experience and input device reliability.

8. ThinkPad X1 Carbon Gen 8 Professional Reassembly: Business-Grade Restoration

📋 Pre-Reassembly Quality Checklist

Component Verification :

All screws accounted for and organized

No leftover components or tools inside chassis

All connectors properly seated and secured

Thermal paste applied if needed

Cleaning & Preparation :

Remove dust from fans and heatsinks with compressed air

Clean keyboard and touchpad surfaces with isopropyl alcohol

Wipe down interior surfaces

Clean port openings and vents

🔧 Professional Reassembly Sequence

Internal Components First :

Install SSD and ensure proper seating

Reconnect all internal cables (keyboard, touchpad, speakers)

Verify no cables obstruct fan movement

Ensure proper cable routing through guides

Keyboard & Palm Rest Assembly :

Connect keyboard ribbon cable (secure ZIF connector)

Connect TrackPoint cable if separated

Align keyboard with chassis guides

Secure with proper screws in correct sequence

Display Reinstallation :

Connect display cable and antenna wires

Align hinge mounts properly

Secure with Torx T5 screws (proper torque)

Verify smooth opening/closing operation

Bottom Case Installation :

Align case with chassis guides

Press around perimeter to engage all clips

Install screws in correct locations and order

Ensure no gap between case and chassis

🔩 Precision Screw Management

Screw Type

Quantity

Location

Torque Specification

Notes

Phillips #00 (4mm)

5

Front edge bottom case

2.5-3.5 inch-pounds

Black finish

Phillips #00 (6mm)

2

Rear edge bottom case

3.5-4.5 inch-pounds

Black finish

Torx T5

4

Hinge mounts

4.0-5.0 inch-pounds

Security screws

Phillips #00 (3mm)

8

Palm rest assembly

2.0-3.0 inch-pounds

Various lengths

📞 Professional Cable Management

Ribbon Cable Best Practices :

Ensure connectors are fully seated and locked

Route cables through original guides and channels

Avoid sharp bends (minimum radius 5mm)

Keep away from heat sources and moving parts

Power Cable Connections :

Connect battery last, after visual inspection

Ensure firm connection to motherboard

Verify no pin damage or bending

Test connection with gentle tug

✅ Professional Quality Control

Visual Inspection :

No visible gaps between panels

All screws installed and flush with surfaces

No tool marks or scratches on exterior

Clean, professional appearance

Functional Testing :

Keyboard and touchpad responsiveness

All ports recognize connected devices

Display opens and closes smoothly

No unusual noises from fans or components

Performance Verification :

Boot into BIOS successfully

All components detected properly

Temperatures within normal range

No error messages during boot

🚫 Common Reassembly Mistakes to Avoid

Over-tightening Screws :

Can strip threads or damage components

Use finger-tight plus quarter turn with screwdriver

Stop when screw is flush with surface

Follow proper torque specifications

Missed Connections :

Double-check all ribbon cable connections

Verify antenna connections for WiFi

Ensure display cable fully seated and locked

Test all functions before final closure

Incorrect Screw Placement :

Using long screws in short holes

Mixing screw types between components

Refer to pre-disassembly photos

Use magnetic project mat for organization

🔍 Comprehensive Final Testing

Basic Functionality :

Power on with AC adapter first

Test battery charging functionality

Verify all keys work on keyboard

Check touchpad and TrackPoint responsiveness

Performance Benchmarks :

Run UserBenchmark quick test

Check temperatures with HWiNFO

Verify fan operation at different speeds

Test audio through speakers and headphones

Stress Testing :

Run Prime95 for CPU stability (15 minutes)

Test storage with CrystalDiskMark

Monitor for thermal throttling

Check for any error messages

✨ Professional Finishing Touches

Exterior Presentation :

Wipe down with microfiber cloth

Clean screen with appropriate cleaner

Remove any fingerprints from surfaces

Apply keyboard protector if including accessories

Documentation Package :

Take high-quality photos of completed reassembly

Record benchmark results and performance data

Create summary of repairs and upgrades performed

Include before/after documentation

Professional Packaging :

Use original Lenovo box if available

Include all appropriate accessories

Provide documentation package

Ensure professional presentation

💼 Business Value Impact

Quality Factor

Value Impact

Corporate Buyer Appeal

Perfect Reassembly

+20-25% value

Extremely High

Professional Documentation

+15-20% value

Very High

Performance Testing

+10-15% value

High

Clean Appearance

+5-10% value

Moderate to High

💡 Corporate Premium Tip: ThinkPads with documented professional reassembly and comprehensive testing typically sell for 30-40% more than untested units, as business buyers value reliability evidence and professional service history.

9. ThinkPad X1 Carbon Gen 8 Post-Repair Testing & Diagnostics: Professional Validation

🎯 Testing Philosophy & Business Standards

Comprehensive Validation :

Ensure all repairs meet ThinkPad quality standards

Verify no new issues were introduced during service

Confirm system stability under business workloads

Document performance for corporate buyers

Enterprise Testing Protocols :

Follow industry-standard testing methodologies

Use reproducible testing procedures

Create detailed documentation for business clients

Provide transparency through verified results

🔧 Hardware Component Validation

Component

Testing Method

Success Criteria

Professional Tools

CPU & Thermal System

Stress test, temperature monitoring

No throttling, temps under 90°C

Prime95, HWiNFO64

RAM

Memory validation, error checking

Zero errors, full capacity detected

MemTest86, Windows Memory Diagnostic

NVMe SSD

Speed test, SMART data review

Expected speeds, good health status

CrystalDiskMark, CrystalDiskInfo

Battery System

Capacity test, charge/discharge cycles

>80% design capacity, holds charge

BatteryInfoView, Lenovo Vantage

Display & Input

Pixel check, input responsiveness

No dead pixels, perfect input response

EIZO Monitor Test, Keyboard Tester

💻 Software & Performance Validation

Operating System Integrity :

Clean Windows 10/11 Professional installation

All drivers installed from Lenovo Support Site

Latest BIOS and firmware updates

No error messages in Event Viewer

Performance Benchmarking :

Run UserBenchmark for overall system score

CPU-Z stress test for processor stability

CrystalDiskMark for storage performance

Document scores for comparison and verification

⚡ Comprehensive Stress Testing

CPU Stress Test :

Run Prime95 Small FFTs for 1 hour

Monitor temperatures with HWiNFO64

Watch for thermal throttling

Check for computation errors

Integrated Graphics Test :

Use FurMark stress test

Run for 30 minutes minimum

Monitor for artifacts or crashes

Check temperature stability

Memory Stress Test :

Run MemTest86 for 4 complete passes

Note any errors (should be zero)

Test each module individually if errors occur

🎮 Real-World Business Testing

Productivity Suite Testing :

Microsoft Office 365 application testing

Multiple browser tabs with video playback

PDF rendering and editing performance

Virtual meeting software testing

Connectivity Validation :

WiFi speed test (5GHz and 2.4GHz networks)

Bluetooth device pairing and file transfer

All USB ports with various devices

Thunderbolt 4 functionality testing

Ethernet via docking station testing

🌡️ Thermal Performance Validation

Business Scenario

Maximum Temperature

Expected Fan Behavior

Performance Standard

Idle (Desktop)

40-50°C

Quiet or silent

No throttling

Web Browsing

50-65°C

Intermittent low speed

Smooth performance

Office Productivity

65-80°C

Consistent medium speed

No slowdowns

Stress Test

80-95°C

High speed, may be loud

Minimal throttling acceptable

🔋 Battery Health & Performance

Capacity Verification :

Run powercfg /batteryreport in Command Prompt

Check designed vs actual capacity

Document charge cycle count

Verify Lenovo Vantage battery status

Runtime Validation :

Set power saver mode, 50% brightness

Video playback until shutdown

Document actual vs expected runtime

Test Rapid Charge functionality

Charge Cycle Testing :

Time 0-80% charge duration (Rapid Charge)

Verify charging indicator operation

Check for consistent charging rate

Test Conservation Mode if enabled

📊 Professional Documentation Protocol

Performance Records :

Screenshot all benchmark results with timestamps

Record temperatures during stress tests

Document any anomalies or observations

Create performance summary report

Visual Documentation :

Photos of system running tests

Video of fan operation under load

Close-ups of display quality

Input device functionality demonstrations

Final Validation Report :

Summary of all tests performed

Comparison to ThinkPad performance standards

Recommendations for optimal usage

Warranty and support information

💼 Business-Ready Validation

Enterprise Feature Testing :

dTPM 2.0 security chip functionality

Intel vPro capabilities (if equipped)

BitLocker encryption testing

Windows Hello fingerprint and facial recognition

Corporate Imaging Preparation :

Clean Windows installation with necessary drivers

Remove all personal data and accounts

Create system restore point

Prepare for enterprise deployment

✅ Final Quality Assurance

Visual Inspection :

No visible signs of repair

All screws properly installed and undamaged

Clean, professional appearance

No gaps or misalignments

Functional Verification :

All ports and connections working

Keyboard and input devices perfect

Display and audio functioning properly

Wireless connectivity stable

💡 Corporate Validation Tip: ThinkPads with comprehensive testing documentation and professional validation results sell for 25-30% more than untested systems, as enterprise buyers require evidence of reliability and performance for business deployment.

10. Maximizing ThinkPad X1 Carbon Gen 8 Resale Value: Professional Business Strategy

📈 2024 Business Laptop Market Analysis

Corporate Demand Trends :

Strong demand for reliable business laptops

Remote work driving need for portable productivity

Companies seeking cost-effective refresh options

IT departments valuing enterprise-grade features

ThinkPad-Specific Advantages :

Brand recognition and business reputation

Military-grade durability standards (MIL-STD-810H)

Enterprise security features (dTPM, vPro optional)

Excellent keyboard reputation among professionals

💰 Competitive Pricing Strategy

Configuration

Base Market Value

After Professional Upgrade

Business Premium

i5/8GB/256GB

$450-$550

$550-$650

+20-25%

i5/16GB/512GB

$600-$700

$750-$850

+20-25%

i7/16GB/512GB

$700-$800

$850-$950

+20-25%

i7/16GB/1TB

$800-$900

$950-$1100

+20-25%

✨ Professional Value Enhancement

Performance Upgrades :

1TB SSD upgrade: +$150-$200 value

Battery replacement: +$100-$150 value

Thermal repaste: +$75-$100 value

Clean Windows install: +$50 value

Cosmetic Improvements :

Keyboard replacement: +$100-$150 value

Professional cleaning: +$50 value

Palm rest replacement: +$75 value

Full exterior refurbishment: +$150-$200 value

📝 Professional Listing Optimization

Title Keywords :

"ThinkPad X1 Carbon Gen 8 Business Laptop [Specs]"

Include: "Professionally Refurbished", "Tested", "Warranty"

Mention key features: "USB-C", "2K Display", "Backlit Keyboard"

Add: "Enterprise Ready", "Business Grade"

Description Essentials :

Lead with benchmark scores and test results

Detail all repairs and upgrades performed

Include battery health percentage and cycle count

Specify included accessories and original packaging

Visual Content Strategy :

15+ high-quality photos from all angles

Video showing boot-up and operation

Close-ups of keyboard and screen quality

Photos of benchmark results on screen

📊 Professional Documentation Package

Performance Proof :

UserBenchmark results with timestamps

Battery health report with cycle count

Temperature stress test results

SSD health and remaining lifespan metrics

Repair Documentation :

Before/after photos of repairs

List of replaced components with part numbers

Testing methodology explanation

Quality control checklist completion

🛡️ Value-Added Warranty Options

Warranty Level

Duration

Cost Impact

Value Added

30-Day Testing Period

30 days

Included

+$50 value

90-Day Limited Warranty

90 days

+$50 cost

+$100 value

180-Day Parts Warranty

180 days

+$100 cost

+$150 value

1-Year Support

1 year

+$200 cost

+$250 value

🎯 Specific Buyer Targeting

Corporate Clients :

Emphasize reliability and security features

Highlight enterprise-grade components

Offer bulk pricing for multiple units

Provide business documentation package

Remote Professionals :

Focus on portability and battery life

Highlight webcam quality and microphone

Emphasize meeting-ready performance

Students & Academics :

Stress durability and keyboard quality

Highlight compatibility with academic software

Offer student discount pricing

⭐ Transaction Excellence

Professional Packaging :

Original ThinkPad box or high-quality replacement

Proper foam padding and protection

Include all accessories neatly organized

Documentation package included

Shipping Standards :

Priority mail with full insurance

Signature confirmation required

Fast handling time (24-48 hours)

Tracking provided immediately

Business Communication :

Prompt professional responses

Clear return policy stated upfront

Additional photos available on request

Post-sale follow-up

💼 ThinkPad-Specific Value Factors

Brand Premium :

ThinkPad reputation: +15-20% value

Keyboard quality: +10-15% value

Build durability: +10% value

Enterprise features: +5-10% value

Documentation Impact :

Professional repair history: +20% value

Performance testing results: +15% value

Original accessories: +10% value

Warranty remaining: +5-15% value

💡 Enterprise Premium Tip: ThinkPads sold through specialized business platforms with complete documentation and professional warranty typically sell for 30-40% more than those on general marketplaces, as corporate buyers value reliability evidence over lowest price.

Need to Sell Your Lenovo Laptop? Get Instant Cash!

If your ThinkPad X1 Carbon Gen 8 (or other ThinkPad model) has performance issues or you're upgrading to a newer business laptop, we offer premium cash payouts for your device. We buy broken, used, and refurbished ThinkPad laptops—including all X1 Carbon Gen 8 configurations—with free insured shipping and hassle-free evaluations.

Sell Popular Lenovo Models Now: