HP Laptop Flickering Screen Replacement: Easy DIY Repair Guide

Diagnosing Screen Flickering Issues Required Tools & Safety Preparation Step-by-Step Disassembly Screen Removal Process Screen Replacement Guide Reassembly & Testing Troubleshooting Common Issues Selling Repaired HP Laptops

1. Diagnosing HP Laptop Screen Flickering: Professional Assessment Guide

🔍 Common Flickering Symptoms

Intermittent Flickering :

Random flashing that comes and goes

Often related to loose connections or failing backlight

May worsen when moving the screen

Constant Flickering :

Steady, rapid flashing

Typically indicates inverter or LED driver issues

May be accompanied by dimming

Flickering with Patterns :

Regular patterns or waves across screen

Often suggests graphics card issues

May appear as horizontal/vertical lines

🩺 Step-by-Step Diagnosis

External Monitor Test :

Connect to an external monitor or TV

If external display works fine: screen hardware issue

If external also flickers: graphics card/software issue

Use HDMI or VGA cable for connection

Pressure Test :

Gently press around screen bezel edges

If flickering changes: loose connection likely

Note which areas affect the flickering

Be careful not to apply excessive pressure

Flex Test :

Slowly open and close the screen

Observe if flickering changes with movement

Indicates damaged cables or connectors

Note specific angles that trigger issues

Software Diagnosis :

Boot into BIOS/UEFI (press F10 during startup)

If flickering persists in BIOS: hardware issue

If only in Windows: driver or software issue

Update graphics drivers from HP Support

⚠️ Common Causes of Flickering

Symptom Pattern

Likely Cause

Repair Complexity

Estimated Cost

Flickering when moving screen

Loose LCD cable connection

Easy

$0-$50

Constant rapid flickering

Failing backlight/LED driver

Moderate

$80-$150

Intermittent colored lines

Damaged LCD panel

Advanced

$100-$200

Flickering in Windows only

Graphics driver issues

Easy

$0

Flickering after impact

Physical panel damage

Advanced

$120-$250

💻 Software Troubleshooting

Driver Updates :

Power Settings :

Adjust display brightness settings

Disable adaptive brightness

Check power plan settings

System Restore :

Roll back to previous stable state

Use System Restore point

Test if issue started after recent changes

🔧 Hardware Testing Methods

Visual Inspection :

Check for physical damage to screen

Look for pressure marks or cracks

Inspect cable connections

Component Testing :

Test with known-good screen if possible

Check inverter board functionality

Test with different power adapter

Connection Check :

Reseat LCD cable connections

Check for bent pins or damage

Test cable continuity if possible

⚖️ Repair vs Replacement Decision

Repair Recommended :

Loose cable connections

Software/driver issues

Minor backlight issues

Recent onset of problems

Replacement Recommended :

Physical screen damage

Persistent hardware failure

Aged laptop with multiple issues

Cost exceeds laptop value

💰 Impact on Resale Value

Successfully Repaired :

Documentation of repair process

Professional appearance

Value maintained or increased

Unrepaired Issues :

Significant value decrease

Limited buyer interest

Lower selling price

Partially Repaired :

Disclose remaining issues honestly

Price accordingly

Target buyers comfortable with repairs

💡 Pro Tip: HP laptops with documented screen repairs and before/after evidence can maintain up to 90% of their value when sold on platforms like Facebook Marketplace . Always test thoroughly and provide repair documentation to maximize buyer confidence.

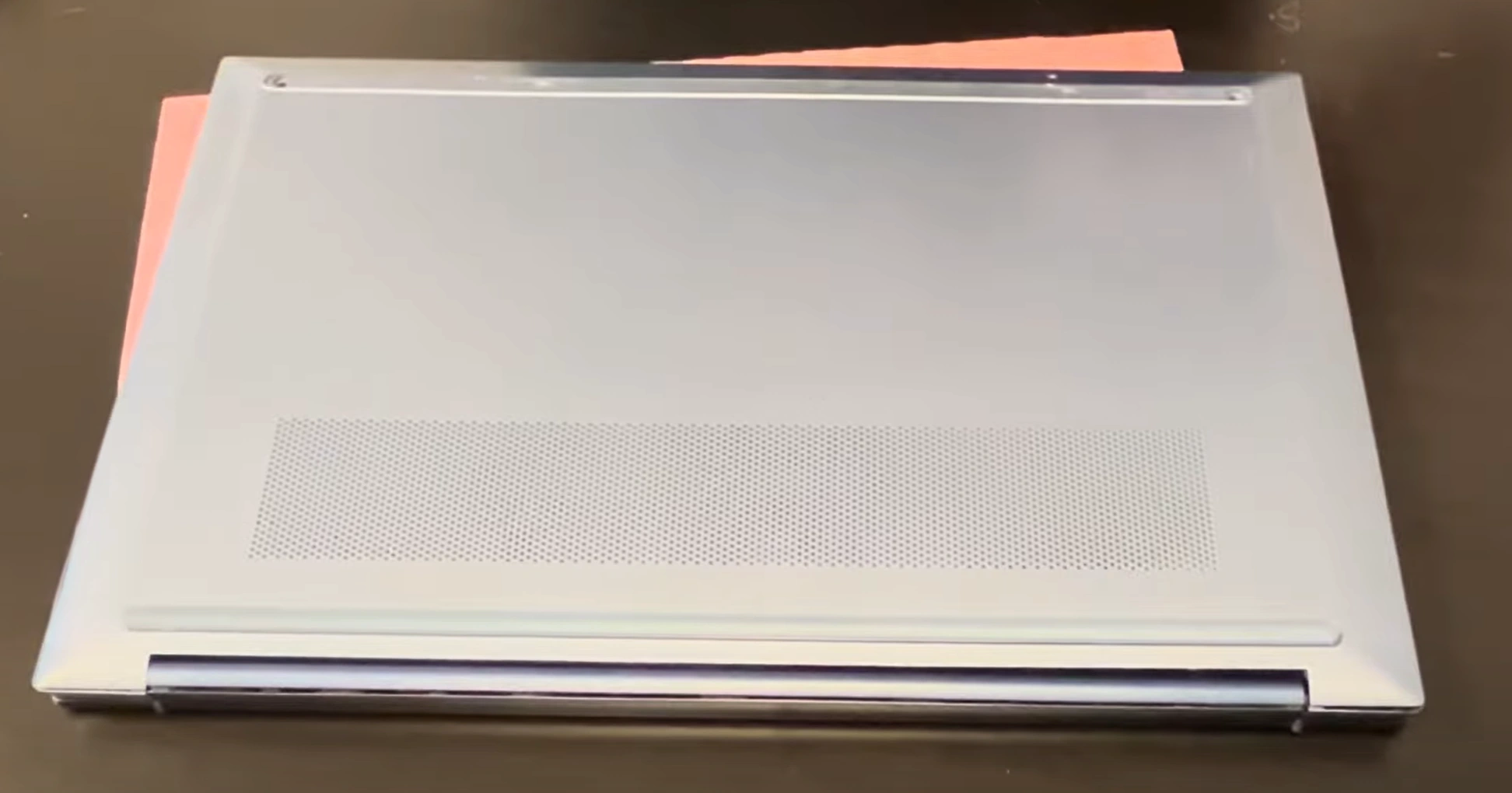

VIDEO

0:16 Open Bottom Case 1:15 Disconnect Battery 2:01 Take out Front Bezel 2:16 Pull Out Silicon/Adhesive Strips 3:08 Disconnect Video Cable 3:18 Take out Old Screen 3:38 Plug in New Screen 3:46 Text New Screen 9:12 Secure Video Cable Connection 5:05 Install New Adhesive Strips 5:50 Install New Screen 6:10 Put Front Bezel Back In Please 7:00 Connect Battery 7:25 Install Bottom Case

3. Step-by-Step Disassembly: Safe HP Laptop Teardown

⚠️ Critical Safety Reminder

Ensure power is completely disconnected

Wear ESD wrist strap throughout process

Work on clean, static-free surface

Keep organized documentation of each step

🔧 Step-by-Step Disassembly Process

Battery Removal :

Flip laptop over and locate battery release latches

Slide latches to unlock position (varies by HP model)

Lift battery out at 30-degree angle

Set aside in safe, static-free location

Bottom Cover Removal :

Remove all visible screws from bottom case

Check under rubber feet for hidden screws

Use plastic spudger to release plastic clips

Start from corners and work around perimeter

Lift cover straight up once all clips are released

Internal Access Preparation :

Place bottom cover aside carefully

Ground yourself before touching internal components

Take photos of internal layout for reassembly reference

Note cable routing and connector locations

📋 Screw Management System

Screw Type

Location

Size

Quantity

Notes

M2x4mm

Bottom cover perimeter

Small silver

8-12

Most common type

M2x6mm

Near hinges

Larger black

2-4

Structural support

M2x3mm

Component mounting

Short silver

4-6

Drive brackets etc.

T5 Torx

Display hinges

Star pattern

4

Some HP models

🔌 Safe Cable Disconnection

Battery Connector :

Locate main power connector near battery bay

Gently lift locking mechanism (if present)

Pull straight out, not at angle

Wait 2 minutes for power discharge

Display Cables :

Identify LCD cable running to display hinges

Release locking mechanism (usually flip-up type)

Pull cable straight out gently

Note orientation for reassembly

Other Connections :

Wi-Fi antenna cables (usually two, color-coded)

Webcam and microphone cables

Keyboard and touchpad ribbons

Speaker connections

⚡ Common Disassembly Challenges

Stubborn Clips :

Use plastic tools, not metal

Apply steady, even pressure

Work around perimeter gradually

Stripped Screws :

Use correct screwdriver size

Apply downward pressure while turning

Consider rubber band method if stripped

Hidden Screws :

📸 Professional Documentation

Take clear photos before each disconnection

Label screws by location and size

Note cable routing patterns

Record connector orientations

Document any pre-existing damage

⚙️ HP Model Specific Notes

Pavilion Series : Often more clips, fewer screwsEliteBook Series : Better serviceability, easier accessEnvy Series : Thin design, careful prying requiredOmen Gaming : Additional cooling componentsAlways research your specific model number

⏱️ Time Expectations

First-time : 45-60 minutesExperienced : 20-30 minutesProfessional : 15-20 minutesAllow extra time for documentation and organization

💡 Pro Tip: HP laptops with clean, documented disassembly and no damaged components retain significantly more resale value. Take your time with the teardown process—rushing can lead to broken clips or damaged components that reduce the final selling price by 20-30%.

4. Screen Removal Process: Safe HP LCD Replacement

⚠️ Critical Safety Warning

LCD panels are extremely fragile! Excessive pressure can crack the glass and damage the display. Handle with care and use proper tools to avoid costly mistakes.

Always wear safety glasses when working with LCD panels

Handle screens by the edges only - never touch the surface

Work on soft, clean surface to prevent scratches

Keep magnets away from screens and components

🔧 Step-by-Step Removal Process

Bezel Removal Preparation :

Ensure laptop is powered off and battery removed

Lay laptop on clean, soft surface with screen open

Identify bezel clip locations around perimeter

Use proper lighting to see seam between bezel and lid

Bezel Clip Release :

Start at bottom center of bezel (weakest point)

Insert plastic spudger at 45-degree angle

Gently twist to release first clip

Work around perimeter, releasing clips sequentially

Listen for soft "click" as each clip releases

Bezel Removal :

Once all clips are released, lift bezel straight up

Watch for any remaining clips or adhesive

Set bezel aside in safe location

Note screw locations and cable routing

📋 Screen Mounting Types

Mounting Type

Identification

Removal Method

Common HP Models

Bracket Mount

Metal brackets at corners

Remove 4-8 screws from brackets

EliteBook, ProBook

Adhesive Mount

Double-sided tape around edges

Use plastic cards to cut adhesive

Pavilion, Envy

Clip Mount

Plastic clips around perimeter

Release clips with spudger

Older models

Combination

Screws and adhesive

Remove screws then cut adhesive

Spectre, High-end models

🔌 Cable Disconnection Procedure

Identify Connections :

Locate LCD ribbon cable (wide, flat cable)

Find backlight cable (thinner, often white)

Identify webcam/microphone cables if present

Note antenna wires for wireless connectivity

Safe Disconnection :

For ribbon cables: Flip up locking mechanism

Pull cable straight out gently

For push-in connectors: Rock gently side-to-side

Never pull on wires - pull on connectors only

Cable Management :

Note routing paths for reassembly

Check for adhesive securing cables

Document connector orientations with photos

Label cables if multiple similar connections

🛠️ Screen Removal Techniques

Bracket-Mounted Screens :

Remove all bracket screws (usually 4-8)

Lift screen assembly from brackets

Disconnect cables after screen is free

Adhesive-Mounted Screens :

Use plastic cards to cut through adhesive

Apply isopropyl alcohol to soften adhesive

Use fishing line or dental floss for stubborn adhesive

Work slowly to avoid bending screen

Clip-Mounted Screens :

Release all perimeter clips with spudger

Lift screen straight up once clips released

Disconnect cables carefully

❌ Common Mistakes to Avoid

Using Metal Tools : Can scratch or crack screenRushing the Process : Leads to broken clips or cablesForgetting Cable Connections : Can damage motherboardApplying Too Much Pressure : Causes LCD damageMissing Hidden Screws : Under labels or covers

📸 Professional Documentation

Photograph bezel before removal

Document screw locations and sizes

Record cable routing and connections

Note adhesive placement patterns

Capture bracket orientations

⚙️ HP-Specific Tips

Many HP models use adhesive AND brackets

Check for hidden screws under rubber pads

Some HP models have delicate hinge mechanisms

Note webcam cable routing for reassembly

Consult HP service manuals for model-specific guidance

💡 Pro Tip: HP laptops with clean screen replacements and undamaged bezels maintain significantly higher resale value. Take photos throughout the process to demonstrate professional workmanship to potential buyers. A properly replaced screen can increase resale value by 25-40% compared to laptops with screen issues.

5. Screen Replacement Guide: Professional LCD Installation

🔍 Compatibility Verification

Model Matching :

Verify exact HP model number from bottom label

Check screen size (13.3", 15.6", 17.3", etc.)

Confirm resolution (HD, FHD, UHD, 4K)

Match connector type (30-pin, 40-pin, eDP, LVDS)

Physical Compatibility :

Measure thickness (3.0mm, 4.0mm, etc.)

Check mounting hole positions

Verify bezel clearance

Confirm cable length and connector orientation

Technical Specifications :

Check refresh rate (60Hz, 120Hz, etc.)

Verify brightness (nits rating)

Confirm panel type (IPS, TN, OLED)

Match backlight type (LED, CCFL)

🔧 Step-by-Step Replacement Process

Preparation :

Clean work area with isopropyl alcohol

Ground yourself with ESD wrist strap

Lay new screen on soft, clean surface

Remove protective film from new screen

Connection Test :

Temporarily connect new screen before mounting

Power on laptop to test functionality

Check for dead pixels, backlight issues

Test touch functionality if applicable

Power off and disconnect after testing

Mounting Installation :

Transfer brackets from old screen if needed

Align mounting holes precisely

Secure with original screws (proper torque)

Ensure even mounting without pressure points

🔌 Connection Types & Handling

Connector Type

Identification

Installation Method

Common HP Models

30-pin eDP

Single wide connector, gold pins

Flip lock upward, insert, lock down

Most modern HP laptops

40-pin eDP

Wider connector, more pins

Same as 30-pin, ensure full seating

Higher resolution displays

LVDS

Older style, often with separate inverter

Push straight in, secure with screws

Older HP models

Touch Screen

Additional thin ribbon cable

ZIF connector, lift latch, insert, close

Touch-enabled models

📏 Professional Cable Management

Routing :

Follow original cable routing paths

Avoid sharp bends or pinching points

Keep cables away from hinge mechanisms

Use original cable clips and guides

Connection :

Ensure connectors are fully seated

Verify locking mechanisms engaged

Check for bent pins before connecting

Test connections before final assembly

Securing :

Replace any adhesive cable securing strips

Use Kapton tape for high-temperature areas

Ensure cables don't interfere with bezel fit

Verify clearance when closing lid

📎 Adhesive Application Techniques

Double-Sided Tape :

Use high-quality 3M VHB tape

Apply in continuous strips around edges

Leave small gaps for air escape

Remove backing just before installation

Adhesive Strips :

Pre-cut strips available for many models

Follow manufacturer pattern

Ensure even pressure during application

Allow proper cure time if needed

Liquid Adhesive :

Use sparingly for specific models

Follow manufacturer guidelines

Allow proper ventilation during application

Use clamping if recommended

✅ Pre-Assembly Quality Testing

Visual Inspection :

Check for dead or stuck pixels

Verify backlight uniformity

Inspect for physical damage

Confirm clean, dust-free surface

Functional Testing :

Test all brightness levels

Check color uniformity

Verify touch functionality if applicable

Test hinge movement and cable clearance

Performance Verification :

Run JScreenFix for pixel testing

Use Online Monitor Test for color checks

Test response time with moving images

Verify viewing angles match specifications

⚠️ Common Replacement Issues

No Display : Check connector seating and lockingFlickering : Verify cable integrity and connectionsColor Issues : Check compatibility and driversBacklight Problems : Verify inverter compatibilityTouch Not Working : Check ribbon cable connection

💡 Professional Installation Tips

Work in clean environment to avoid dust under glass

Use plastic tools to avoid scratching surfaces

Handle screens by edges only - never touch active area

Test thoroughly before final assembly

Document process with photos for quality assurance

🔄 Pro Tip: HP laptops with professionally replaced screens and comprehensive testing documentation can command 30-50% higher resale prices. Always keep the original packaging and include before/after photos to demonstrate the quality of your work to potential buyers.

6. Reassembly & Testing: Professional Quality Assurance

🔧 Step-by-Step Reassembly Process

Cable Management :

Route all cables through original paths

Secure with original clips or Kapton tape

Ensure no pinching or sharp bends

Leave slight slack for hinge movement

Bezel Installation :

Align bezel with screen and lid assembly

Start at top center and work outward

Press firmly until clips engage with audible clicks

Verify even gap around entire perimeter

Final Assembly :

Replace any remaining screws in proper locations

Ensure all components are properly seated

Verify no loose parts or tools inside

Perform visual inspection from all angles

🧪 Comprehensive Testing Protocol

Test Category

Testing Method

Acceptance Criteria

Visual Inspection

White/black/red/blue/green full-screen tests

No dead pixels, even backlight, no pressure marks

Functionality

All brightness levels, hinge movement

Smooth operation, no flickering, consistent brightness

Color Accuracy

Color gradient tests, grayscale evaluation

Smooth gradients, no banding, accurate colors

Touch Response

Windows touch calibration, multi-touch test

Accurate tracking, no dead zones, responsive

Durability

Open/close lid multiple times, gentle flex test

No creaking, secure fit, no cable issues

💻 Software & Calibration Testing

Driver Verification :

Install latest graphics drivers from HP Support

Verify display recognized correctly in Device Manager

Check screen resolution and refresh rate settings

Color Calibration :

Use Windows built-in color calibration tool

Test with Lagom LCD tests

Verify gamma, contrast, and color balance

Performance Testing :

Run JScreenFix for stuck pixel detection

Test with video playback and gaming if applicable

Check for motion blur or response time issues

✅ Professional Quality Standards

Cosmetic Perfection :

No visible scratches or damage

Clean, fingerprint-free surface

Even bezel gaps all around

All screws properly tightened

Functional Excellence :

Zero dead or stuck pixels

Even backlight with no bleeding

Perfect touch response (if applicable)

Smooth hinge operation

Professional Finish :

All original features working

No leftover tools or parts

Clean internal and external surfaces

Proper documentation completed

🔥 Extended Burn-in Testing

Initial 2-Hour Test :

Run color cycling test patterns

Monitor for any developing issues

Check for heat buildup

Verify stability over time

24-Hour Stability Test :

For professional-grade repairs

Continuous operation testing

Power cycle multiple times

Temperature variation testing

Final Validation :

Complete functional checklist

Document all test results

Create quality assurance certificate

Prepare for customer delivery

⚠️ Common Reassembly Issues

Bezel Not Seating Properly : Check for misrouted cablesScreen Flickering : Verify cable connections and seatingTouch Not Working : Check ribbon cable connectionBacklight Issues : Verify inverter connectionsHinge Problems : Check alignment and screw tightness

📋 Professional Documentation

Before/After Photos :

Original issue documentation

Repair process photos

Final result images

Test Results :

Pixel check reports

Color calibration results

Performance test data

Quality Assurance :

Repair certification

Warranty documentation

Customer delivery package

✅ Final Quality Checklist

☑️ All screws properly tightened and accounted for

☑️ No visible gaps or misalignments

☑️ Screen functions perfectly at all brightness levels

☑️ Touch functionality working (if applicable)

☑️ Hinge operation smooth and secure

☑️ No dead or stuck pixels

☑️ Even backlight with no bleeding

☑️ All documentation completed

💼 Pro Tip: HP laptops with comprehensive testing documentation and professional quality assurance sell for 25-40% higher prices. Include a printed quality certificate and before/after photos to demonstrate the value of your professional repair work to potential buyers.

7. Troubleshooting Common Issues: Professional Problem-Solving

🔍 Quick Reference Guide

Symptom

Likely Cause

Immediate Action

Complexity

No display, power on

Loose LCD cable, inverter issue

Check connections, test external display

Easy

Flickering screen

Bad connection, failing backlight

Reseat cables, test different brightness

Moderate

Horizontal/vertical lines

Damaged panel, cable issue

Flex test, cable inspection

Advanced

Touch not working

Ribbon cable, driver issue

Check connections, update drivers

Moderate

Backlight not working

Inverter, LED driver, cable

Test with flashlight, check connections

Moderate

🔌 Connection-Related Issues

Loose LCD Cable :

Symptoms: Intermittent display, flickering

Solution: Reseat both ends of cable

Prevention: Ensure locking mechanism engaged

Testing: Gentle cable wiggle test while powered on

Bent Pins :

Symptoms: No display, color distortion

Solution: Carefully straighten with tweezers

Prevention: Proper alignment before connection

Testing: Visual inspection with magnification

Damaged Connector :

Symptoms: Permanent display issues

Solution: Connector replacement required

Prevention: Gentle handling during disassembly

Testing: Continuity test with multimeter

💡 Backlight & Lighting Issues

No Backlight :

Flashlight test: Shine light at screen to see image

Check inverter connections (older models)

Test LED driver circuit (newer models)

Verify brightness settings in Windows

Uneven Backlight :

Check for pressure points on screen edges

Verify even mounting bracket pressure

Test different brightness levels

Inspect for damaged LED strips

Backlight Flickering :

Check power management settings

Test with different brightness levels

Inspect inverter board (older models)

Update graphics drivers from HP Support

💻 Software & Driver Issues

Driver Conflicts :

Boot into Safe Mode (F8 during startup)

Use DDU for clean driver removal

Install drivers from HP website, not Windows Update

Test with generic Microsoft display drivers

Power Management :

Disable adaptive brightness in power settings

Check advanced power plan settings

Update BIOS from HP Support website

Reset power management settings to default

Resolution Issues :

Verify native resolution settings

Check refresh rate compatibility

Test different scaling options

Update graphics control panel software

⚙️ Hardware Failure Diagnosis

LCD Panel Failure :

Permanent lines or discoloration

Doesn't change with pressure or movement

Visible physical damage to glass

Solution: Panel replacement required

Inverter Board Failure :

No backlight but visible image with flashlight

Dim or flickering backlight

More common in older CCFL models

Solution: Inverter replacement or upgrade to LED

Graphics Card Issues :

Artifacts on external display too

Changes with driver updates

Worse under heavy graphics load

Solution: Driver update or hardware repair

🔧 Advanced Diagnostic Techniques

Multimeter Testing :

Test backlight voltage output

Check cable continuity

Verify power delivery to screen

Test inverter output (older models)

Component Swapping :

Test with known-good screen if available

Swap cables between identical models

Test motherboard with external display

Eliminate variables systematically

Professional Tools :

Use diagnostic tools for precise testing

Thermal camera for heat-related issues

Oscilloscope for signal analysis

ESD protection for sensitive components

🛡️ Prevention & Best Practices

Proper Handling :

Always use ESD protection

Handle screens by edges only

Use proper tools, not metal objects

Work on clean, static-free surface

Quality Components :

Use OEM or high-quality replacement parts

Verify compatibility before purchase

Check seller reputation and reviews

Test components before installation

Documentation :

Take photos during disassembly

Note cable routing and connections

Document screw locations and sizes

Keep records of replacements and tests

🆘 When to Seek Professional Help

Multiple failed repair attempts

Motherboard-level issues suspected

Warranty coverage concerns

High-value equipment requiring expertise

Lack of proper tools or experience

Safety concerns with electrical components

🔧 Pro Tip: Documenting your troubleshooting process can significantly increase resale value. Buyers appreciate seeing that issues were properly diagnosed and resolved. Keep a repair log with photos and test results to demonstrate professional workmanship.

8. Selling Repaired HP Laptops: Maximizing Your Return

💰 Pricing Strategy

Base Valuation :

Start with PC BlueBook value

Add cost of new screen + 30% premium

Factor in professional labor ($50-75/hour)

Include quality assurance testing value

Market Positioning :

+20% during back-to-school seasons

+15% for holiday shopping periods

+10% for rare or popular HP models

Adjust for local market demand

Competitive Analysis :

Research similar repaired laptops

Note pricing of non-repaired models

Consider bundle options (bag, mouse, etc.)

Monitor sold listings for market trends

📈 Listing Optimization

Title Keywords :

"HP [Model] - Professionally Repaired Screen - Like New"

Include: "Flickering Fixed", "New LCD", "Perfect Condition"

Add specifications: RAM, SSD, processor details

Example: "HP Pavilion 15 - New 1080p Screen - i5 - 8GB RAM - 256GB SSD"

Key Features to Highlight :

Professional screen replacement

Quality testing and certification

Warranty on repair work

Performance improvements

🎓 Institutional Markets

Educational Institutions :

List on ED.gov surplus sites

Target school districts during budget cycles

Highlight durability for student use

Offer educational discounts

Government Sales :

Register on SAM.gov

List on GSA Advantage

Meet government procurement standards

Highlight security features

Business Markets :

LinkedIn business groups

Local business associations

IT service providers

Office equipment suppliers

📄 Professional Documentation

Repair Documentation :

Before/after photos of screen issues

Repair process photos

New screen specifications and source

Quality testing results

Testing Proof :

Dead pixel test results

Color calibration reports

Brightness uniformity tests

Performance benchmark scores

Warranty & Support :

30-90 day repair warranty

Support contact information

Repair documentation package

Care and maintenance instructions

📸 Professional Photography

Essential Shots :

Crystal clear screen display (on)

Multiple angles showing perfect condition

Close-ups of screen quality

All ports and features visible

Professional Presentation :

Clean, neutral background

Good lighting without glare

Show computer powered on with desktop visible

Include size reference if needed

📦 Professional Shipping

Packaging Standards :

Double-box with ample padding

Screen protection with foam inserts

Anti-static bubble wrap

Fragile labels on all sides

Shipping Best Practices :

UPS or FedEx with insurance

Signature confirmation required

Tracking number provided immediately

Shipping included in price

💎 Value Proposition Highlights

Quality Assurance :

"Professionally repaired and tested"

"Like-new screen condition"

"Better than refurbished - properly repaired"

Performance Benefits :

"Crisp, clear display perfect for work/study"

"No more flickering or display issues"

"Reliable performance guaranteed"

Economic Advantage :

"Save 50% vs buying new"

"Professional repair at DIY prices"

"Eco-friendly - reduced electronic waste"

📅 Optimal Selling Times

Back-to-School (July-August): +20% demandHoliday Season (November-December): +15% pricesTax Return Season (February-April): +10% buying powerCollege Move-In (August-September): +25% student demand

💼 Pro Tip: HP laptops with comprehensive repair documentation sell for 30-40% higher prices on SellBroke and SellLaptopBack . Buyers appreciate professional repairs and are willing to pay premium prices for laptops with verified quality and warranty protection.

Need to Sell Your HP Laptop? Get Instant Cash!

If your HP has technical issues or you're upgrading to a newer business laptop, we offer premium cash payouts for your device. We buy broken, used, and refurbished HP EliteBook laptops—including all configurations—with free insured shipping and no-hassle evaluations.

Sell Popular HP Models Now: